Hi team.

My customer wants to use this Isolator.

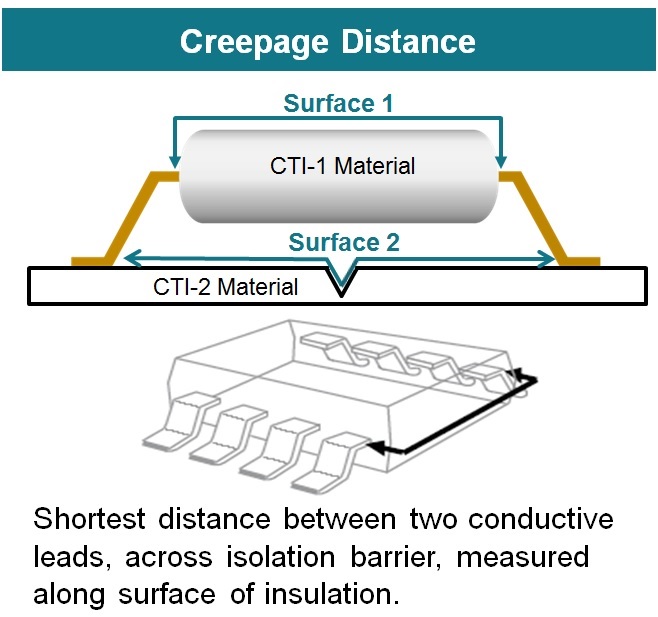

they wants to need more creepage is over 9mm in 450Vrms.

However it clear the voltage of 450Vrms, but the creepage is short of 9mm in recommend layout.

Would you tell me the advice if you have good way?

I checked the "Digital Isolator Design Guide", is it only the way it is listed here?

Best regards

Hayashi