Dear Sirs,

I am working on a new automotive ECU design, which shall be used on heavy duty Diesel powered engines.

Among the features to build into it, one (or more) CAN interfaces are must.

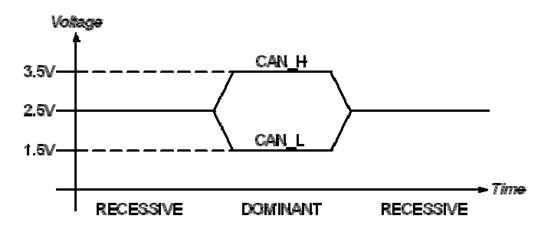

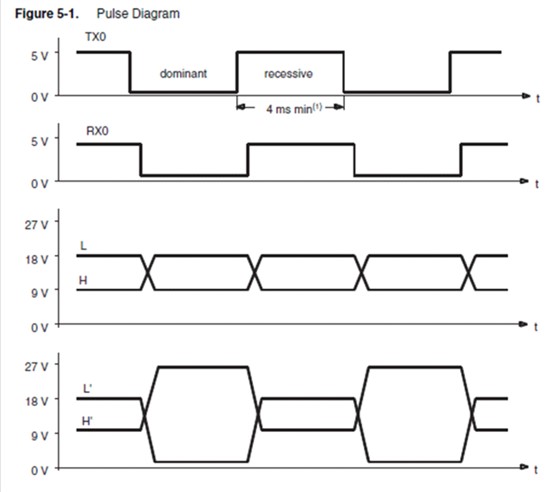

Looking at scope readings from other ECUs, we can see that the actual voltages used are about 9V(low) and 16V (high) levels. Baud rates are fairly low, at 125k, for this specific application.

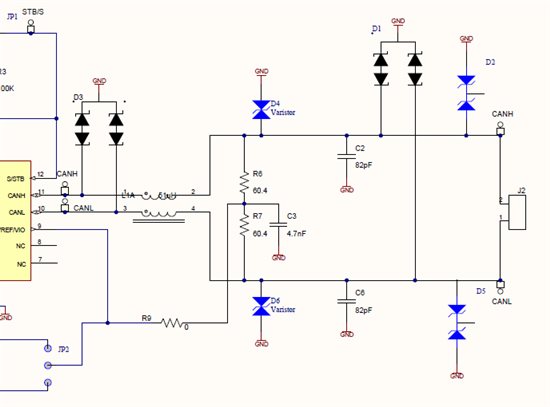

A quick look into TI's product range indicated the SN65HVDA542-5-Q1.

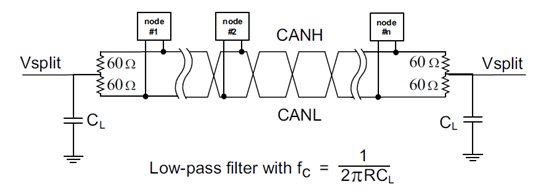

I would kindly ask if this selection is correct and what external components would be required to get the voltage levels we need.

This would allow us to start designing as we purchase the parts. As it is not unusual to any of us, this is quite urgent.

Thanks in advance,

Daniel Sofer

DSA