Other Parts Discussed in Thread: TMS320F280049C

Hey there,

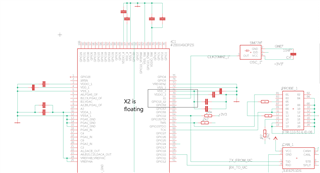

I am experiencing a problem with the CAN module on a TMS320F280049C.

The board i have in front of me is working fine, I am debugging, SCI-communication with another device is working fine. On the LaunchPad (the development board I ordered) with the same exact controller, the CAN bus works without issues.

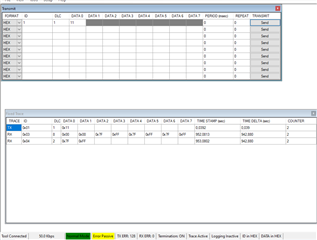

Now I debug the controller on my own board, and the program also runs without issue, stops at a breakpoint set at the pre-written function "CAN_sendMessage()", see screenshot.

Now I am monitoring GPIO32 (CAN-Tx-Pin) to see, if there is any changes in Voltage on that Pin, since the Transceiver is doesnt Transmit messages. And there is nothing. Again, I am using Code that works fine on the LaunchPad. The only change I make is setting the Target Config to TMS320F280049C.ccxml.

I have removed the Transceiver to make sure that there is no interference on that side, with no luck. This is a work project, I am a trainee and surely not experienced.

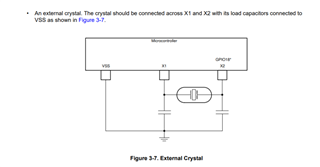

Is there any hardware configuration, some Enable pin I am missing? The Controller has an external 20MHz oscillator on my board as well, as the CAN module needs precise timing. Is there any additional connection I have to mind?

Thank you for any help in advance!

Cheers, Chris

This is what i've found in the datasheet. Could you refer to the datasheet you are referencing?

This is what i've found in the datasheet. Could you refer to the datasheet you are referencing? may this be the issue? meaning if i cut the short and X2 is floating, it may work?

may this be the issue? meaning if i cut the short and X2 is floating, it may work?