Other Parts Discussed in Thread: TMS320F28069

Hi Dear.

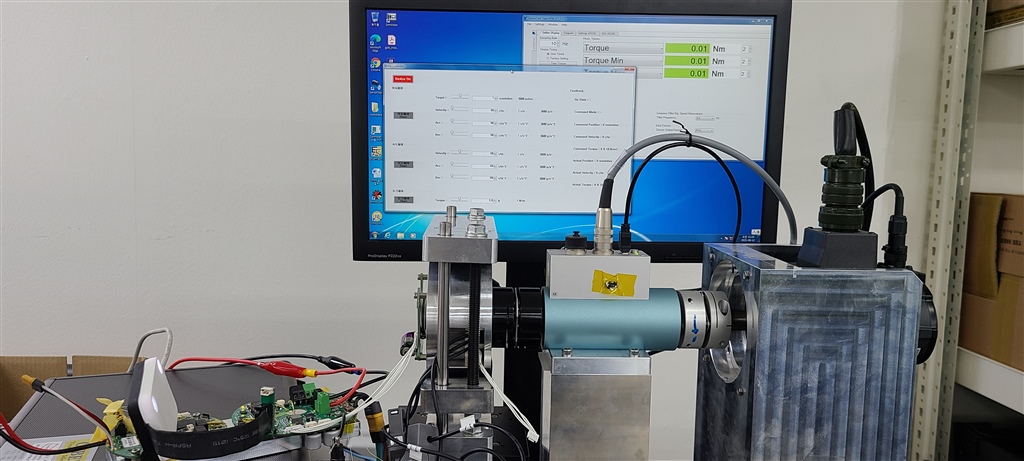

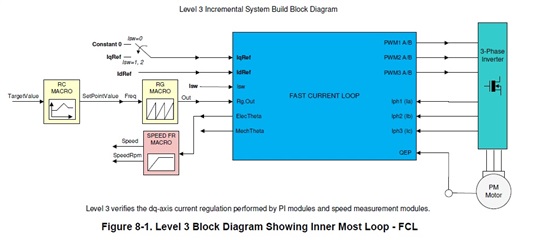

I using the F28388D with application, which is based on the Motor Control Library Build3 Example.

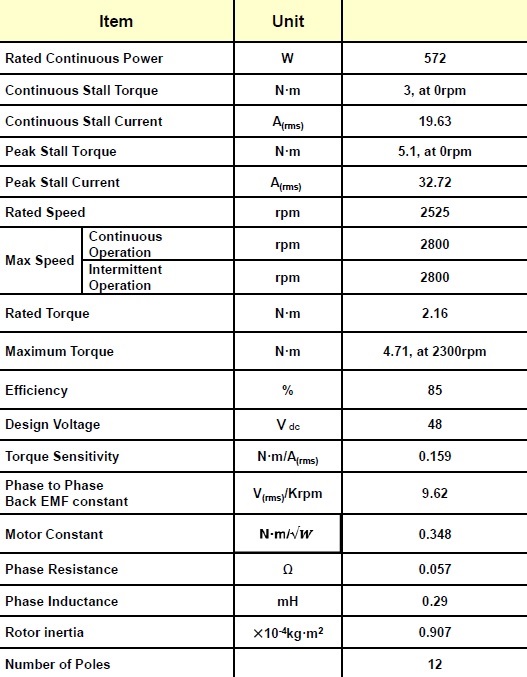

the following is Motor Parameters and configuration

#define CGND HOT //COLD

#define BUILDLEVEL FCL_LEVEL3

#define SAMPLING_METHOD SINGLE_SAMPLING // DOUBLE_SAMPLING //

#define FCL_CNTLR PI_CNTLR // CMPLX_CNTLR //

#define CURRENT_SENSE SHUNT_CURRENT_SENSE //SD_CURRENT_SENSE // LEM_CURRENT_SENSE //

#define RS 0.113 // Stator resistance (ohm)

#define RR NULL // Rotor resistance (ohm)

#define LS 0.000374 // Stator inductance (H)

#define LR NULL // Rotor inductance (H)

#define LM NULL // Magnetizing inductance (H)

#define FLUX 0.962 // BEMF constant (V/Hz)

#define POLES 12 // Number of poles

#define ENC_SLOTS 65536 // Numer of slots in the encoder

#define M_ID_START 0.04 // alignment reference d-axis current, 0.06 -> 8A Injected

#define M_IQ_LI5 0.04 // reference q-axis current for level5

#define M_IQ_LN5 0.00/*0.04*/ // ref q-axis current for no level5

//

// Define the base quantites

//

#define BASE_VOLTAGE 38.1 // 66/sqrt(3) = 38.1 by alex //38.1 //236.14 // Base peak phase voltage (volt), Vdc/sqrt(3)

#define BASE_SHUNT_CURRENT 47.4 // Base peak phase current (amp),

// Max. measurable peak curr.

#define Current_Limit 36.0 //36.0

#define BASE_LEM_CURRENT 12.0 // ----- do -----

#define BASE_TORQUE // Base torque (N.m)

#define BASE_FLUX // Base flux linkage (volt.sec/rad)

#define BASE_FREQ 250 // Base electrical frequency (Hz)

// rpm = 120*Base_freq/poles

when i run the motor, the torque value under 1A, its operation ok,

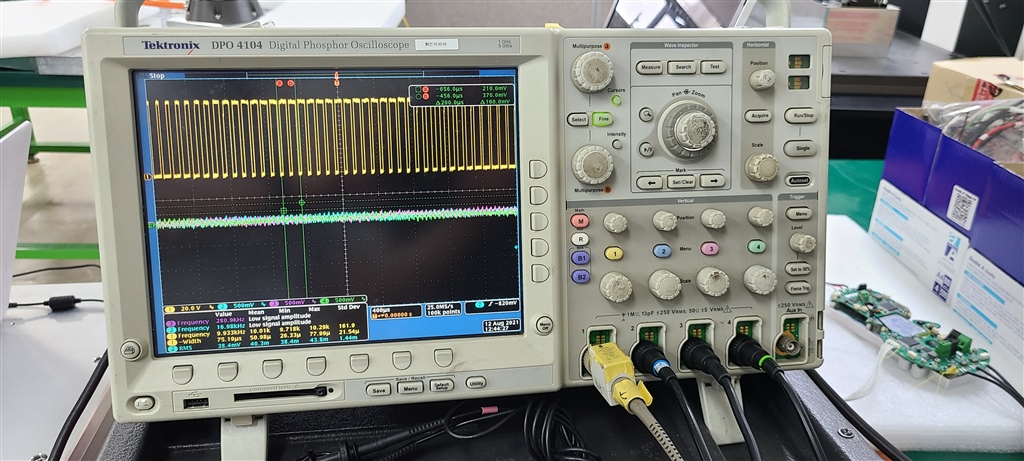

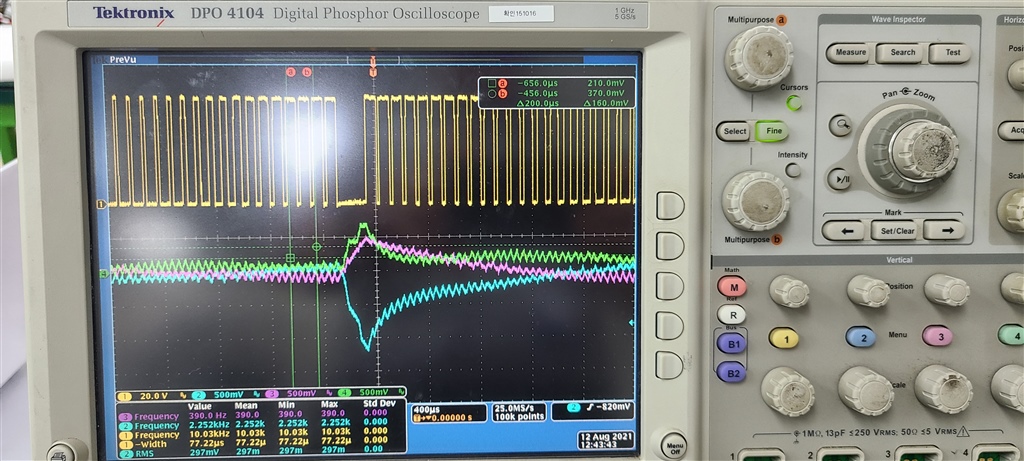

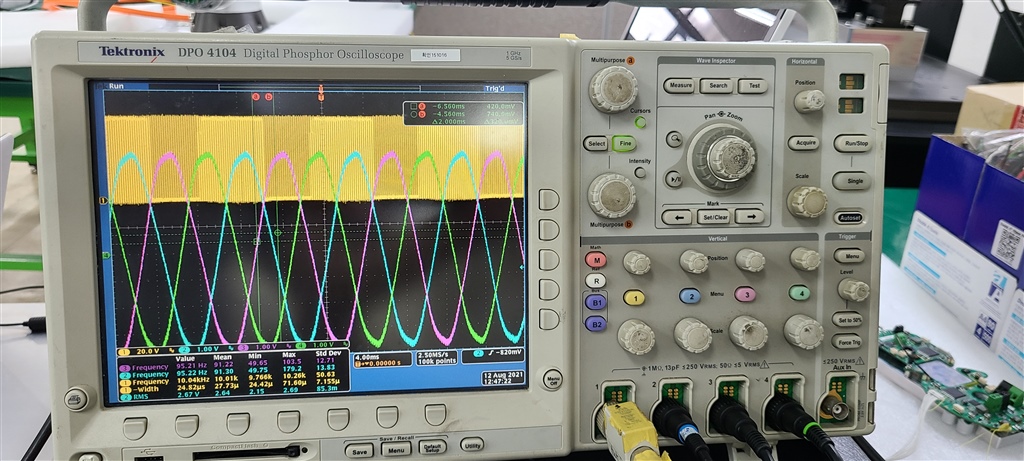

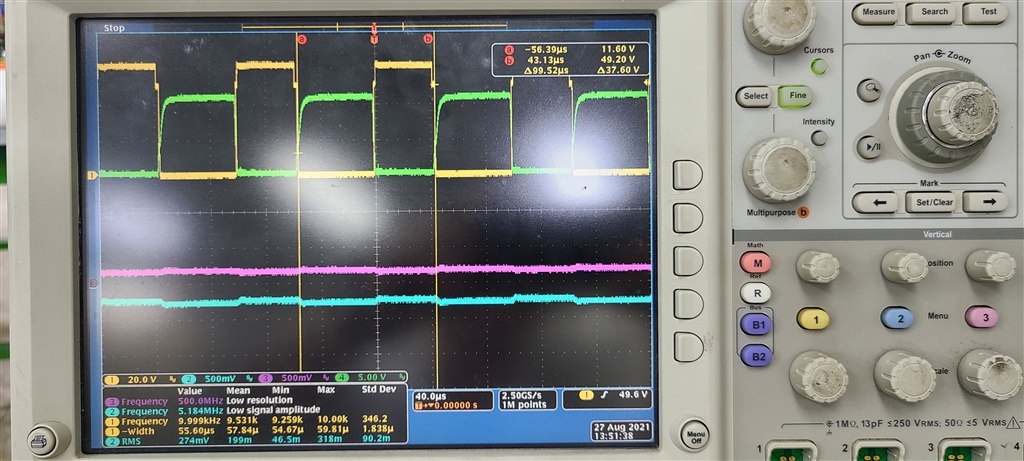

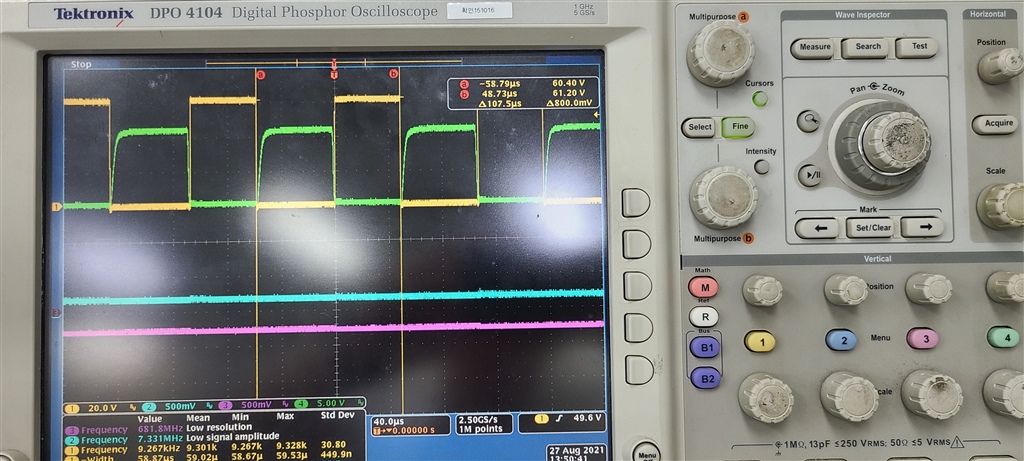

but over 1A, then speed is about 1800 rpm, the Current Sine wave is distort(above picture)

i guess there are some limit conditions, but can't find.

thank you