Hi Team,

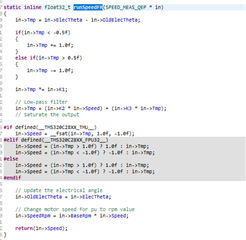

I am currently using TIDM-02007 for testing. The code I tested is Level4.

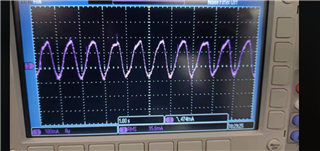

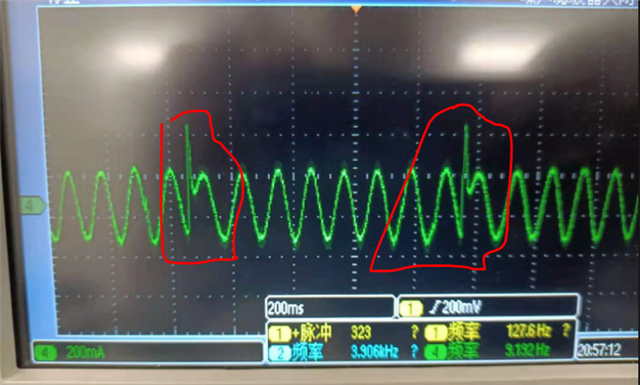

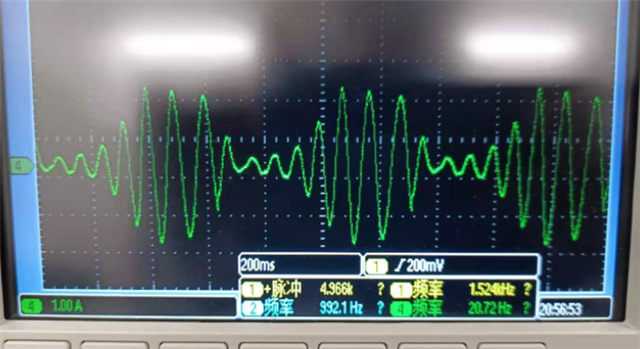

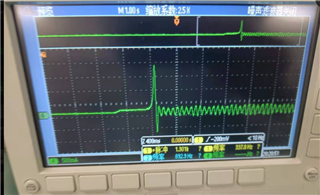

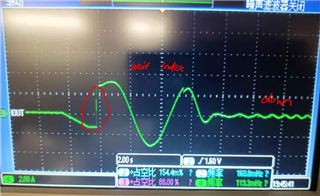

During the start-up process, the motor will shake.This seems to be caused during the process from "ENC_ALIGNMENT" to "ENC_WAIT_FOR_INDEX"

As shown in the figure, when the current has a sudden change, the motor will vibrate.

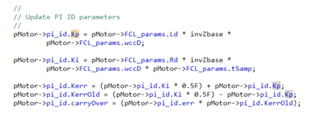

May I ask what causes this? Should we improve this situation?Is it the impact of not setting the parameters?

Thanks

Jenson