Other Parts Discussed in Thread: DRV8301, MOTORWARE

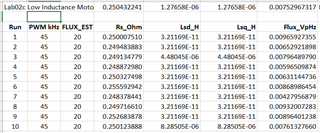

I have a TI Instaspin motorware based project that runs on a custom board using a DRV8301 and TI MOSFETs. These turn a 24V BLDC motor that is embedded in a water pump. The software was based on motorware v16 proj_lab11a. The issue is that at a speed just below nominal rated RPM of 3450 the motor spins up out of control. I added datalog.c to the project so I could plot out angle, current and voltage of the controller to see what's happening. Here are the waveforms of the motor running just below the nominal speed.

It looks like the current waveform has an oscillation overlaid on it and the angle and voltage look normal. Should I adjust the gain settings on the current PI loops? And if so how would I go about that. I've attempted adjustments the gains on both Id and Iq based on what I've read in the Instaspin Lab manual but haven't had any luck making improvements.

Thanks in advance