Part Number: LAUNCHXL-F280049C

Hello,

I am looking at implementing the field weakening control according to lab 13 in this guide: https://dev.ti.com/tirex/explore/node?node=AB7tA2xX4yXlPxzl5o3s1w__0.jXikd__LATEST

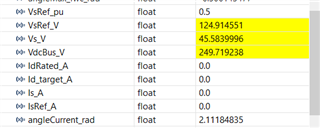

We are using the default parameters from that lab:

I am having some trouble getting this to work. With fwc code included (enable flag set high or low), the motor makes a high pitched noise when commanding lower speeds that is not present without the fwc. The motor seems to run with the fwc enabled, but the top speed is slightly lowered if anything (on the order of 20-30rpm/1700 lower). Here are some specific questions/concerns I have:

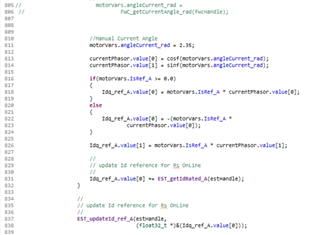

1. We would like to use fwc independent of MTPA. It doesn't seem like this would cause any problems, but are there any considerations for this beyond removing the MTPA calculations and changing this line:

to just the fwc angle?

to just the fwc angle?

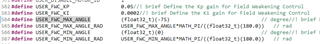

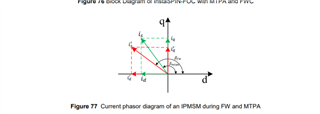

2. How do these current angles make sense? referencing this figure from the lab, do we not want current angles in the range (90,180) degrees to get negative Id currents in the case of field weakening?. Also why is the min lower than the max in the case of the lab? I feel as though we are misunderstanding how this is defined or used.

3. When commanding high speeds with fwc enabled, we are seeing current spikes that cause the motor to lock at 0rpm, and max current is pulled from our power supply (bus voltage drops low in this case without triggering undervoltage fault).

I am expecting the fwc to take our motor to speeds above 2000rpm based on testing done with a different drive that uses field weakening. Presently, we are seeing ~1750rpm max speeds.

Thanks in advance,

Coleman M Keding