Part Number: INSTASPINUNIVERSALGUI

Other Parts Discussed in Thread: MOTORWARE, TMDSHVMTRINSPIN

Dear team:

My customer has the following problems with some parameters identified by the GUI:

1, Can the moment of inertia and friction coefficient identified through GUI be directly applied to his system? In other words, does it have to be re identified in different unit systems (such as different unit frequencies and unit currents)?

2, Whether the flux parameter flux (V / Hz) identified by the GUI is equal to that in formula 26 for converting moment of inertia φ EMF?

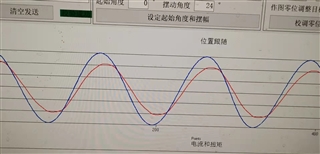

3, Can he directly use the motion controller instead of the move module? Because he wants to control the motor to track the sinusoidal signal.

Best regards