Part Number: TMS320F280025C

Other Parts Discussed in Thread: LAUNCHXL-F280025C

I used the General motor Control lab example and I saw that the example needed to reach a certain RPM to enable the speed ring as follows:

if(fabsf(obj->speed_Hz) > obj->speedStart_Hz)

{

TRAJ_setMaxDelta(obj->trajHandle_spd,

(obj->accelerationMax_Hzps / objUser->ctrlFreq_Hz));

#if defined(MOTOR1_ISBLDC)

ISBLDC_updateThresholdInt(obj->isbldcHandle, obj->speed_int_Hz);

#if (DMC_BUILDLEVEL >= DMC_LEVEL_4)

PI_setMinMax(obj->piHandle_spd, -obj->maxCurrent_A, obj->maxCurrent_A);

#else

PI_setMinMax(obj->piHandle_spd, -1.0f, 1.0f);

#endif // DMC_BUILDLEVEL <= DMC_LEVEL_3

#else // !MOTOR1_ISBLDC

PI_setMinMax(obj->piHandle_spd, -obj->maxCurrent_A, obj->maxCurrent_A);

SVGEN_setMode(obj->svgenHandle, obj->svmMode);

#endif // !MOTOR1_ISBLDC

if(obj->motorState == MOTOR_CL_RUNNING)

{

obj->stateRunTimeCnt++;

if(obj->stateRunTimeCnt == obj->fwcTimeDelay)

{

obj->Idq_out_A.value[0] = 0.0f;

obj->motorState = MOTOR_CTRL_RUN;

obj->mctrlState = MCTRL_CONT_RUN;

}

}

}

else

{

TRAJ_setMaxDelta(obj->trajHandle_spd,

(obj->accelerationStart_Hzps / objUser->ctrlFreq_Hz));

#if defined(MOTOR1_ISBLDC)

#if (DMC_BUILDLEVEL >= DMC_LEVEL_4)

if(obj->speed_int_Hz > 0.0f)

{

PI_setMinMax(obj->piHandle_spd, 0.0f, obj->startCurrent_A);

}

else

{

PI_setMinMax(obj->piHandle_spd, -obj->startCurrent_A, 0.0f);

}

#else // (DMC_BUILDLEVEL < DMC_LEVEL_3)

PI_setMinMax(obj->piHandle_spd, -1.0f, 1.0f);

#endif // DMC_BUILDLEVEL < DMC_LEVEL_3

#else // !MOTOR1_ISBLDC

if(obj->speed_int_Hz >= 0.0f)

{

PI_setMinMax(obj->piHandle_spd, 0.0f, obj->startCurrent_A);

}

else

{

PI_setMinMax(obj->piHandle_spd, -obj->startCurrent_A, 0.0f);

}

#endif // !MOTOR1_ISBLDC

}

I wonder why? What's the point? Can I start the motor and just use the speed ring? I tried to modify it like this:

//if(fabsf(obj->speed_Hz) > obj->speedStart_Hz)

//{

TRAJ_setMaxDelta(obj->trajHandle_spd,

(obj->accelerationMax_Hzps / objUser->ctrlFreq_Hz));

#if defined(MOTOR1_ISBLDC)

ISBLDC_updateThresholdInt(obj->isbldcHandle, obj->speed_int_Hz);

#if (DMC_BUILDLEVEL >= DMC_LEVEL_4)

PI_setMinMax(obj->piHandle_spd, -obj->maxCurrent_A, obj->maxCurrent_A);

#else

PI_setMinMax(obj->piHandle_spd, -1.0f, 1.0f);

#endif // DMC_BUILDLEVEL <= DMC_LEVEL_3

#else // !MOTOR1_ISBLDC

PI_setMinMax(obj->piHandle_spd, -obj->maxCurrent_A, obj->maxCurrent_A);

SVGEN_setMode(obj->svgenHandle, obj->svmMode);

#endif // !MOTOR1_ISBLDC

if(obj->motorState == MOTOR_CL_RUNNING)

{

obj->stateRunTimeCnt++;

if(obj->stateRunTimeCnt == obj->fwcTimeDelay)

{

obj->Idq_out_A.value[0] = 0.0f;

obj->motorState = MOTOR_CTRL_RUN;

obj->mctrlState = MCTRL_CONT_RUN;

}

}

//}

//else

//{

// TRAJ_setMaxDelta(obj->trajHandle_spd,

// (obj->accelerationStart_Hzps / objUser->ctrlFreq_Hz));

//#if defined(MOTOR1_ISBLDC)

// #if (DMC_BUILDLEVEL >= DMC_LEVEL_4)

// if(obj->speed_int_Hz > 0.0f)

// {

// PI_setMinMax(obj->piHandle_spd, 0.0f, obj->startCurrent_A);

// }

// else

// {

// PI_setMinMax(obj->piHandle_spd, -obj->startCurrent_A, 0.0f);

// }

// #else // (DMC_BUILDLEVEL < DMC_LEVEL_3)

// PI_setMinMax(obj->piHandle_spd, -1.0f, 1.0f);

// #endif // DMC_BUILDLEVEL < DMC_LEVEL_3

//#else // !MOTOR1_ISBLDC

// if(obj->speed_int_Hz >= 0.0f)

// {

// PI_setMinMax(obj->piHandle_spd, 0.0f, obj->startCurrent_A);

// }

// else

// {

// PI_setMinMax(obj->piHandle_spd, -obj->startCurrent_A, 0.0f);

// }

//#endif // !MOTOR1_ISBLDC

//}

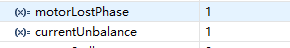

But when I set flagEnableRunAndIdentify to true, after a while I get the moduleOverCurrent error and the motor doesn't respond?

So I want to know the purpose of TI engineer's design? And how to modify the code to start the speed ring directly like LAB5B?

Thanks technologist, best regards.