Other Parts Discussed in Thread: C2000WARE

Dear Experts,

could you please help to clarify below questions related to C2000Ware:

- Error Handling mechanism absent in stack.

- is ASSERT (Error handling) usable for production code.

- Is the stack tested for production? Any modifications required?

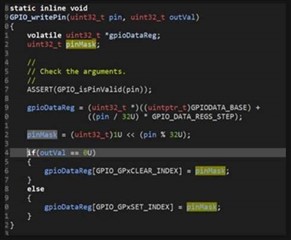

- Memory management: Some functions have input parameters that take 0 or 1 as input but the parameter type is U32. Is there a reason behind same? (Refer code snippet below)

- Most of the stack is implemented as static inline. What is the purpose? Is there a way to not use it in that way?

- Compiler specific Macros, EALLOW, ESTOP, Pragma packing (if any)

Thanks and best regards,

Gregor