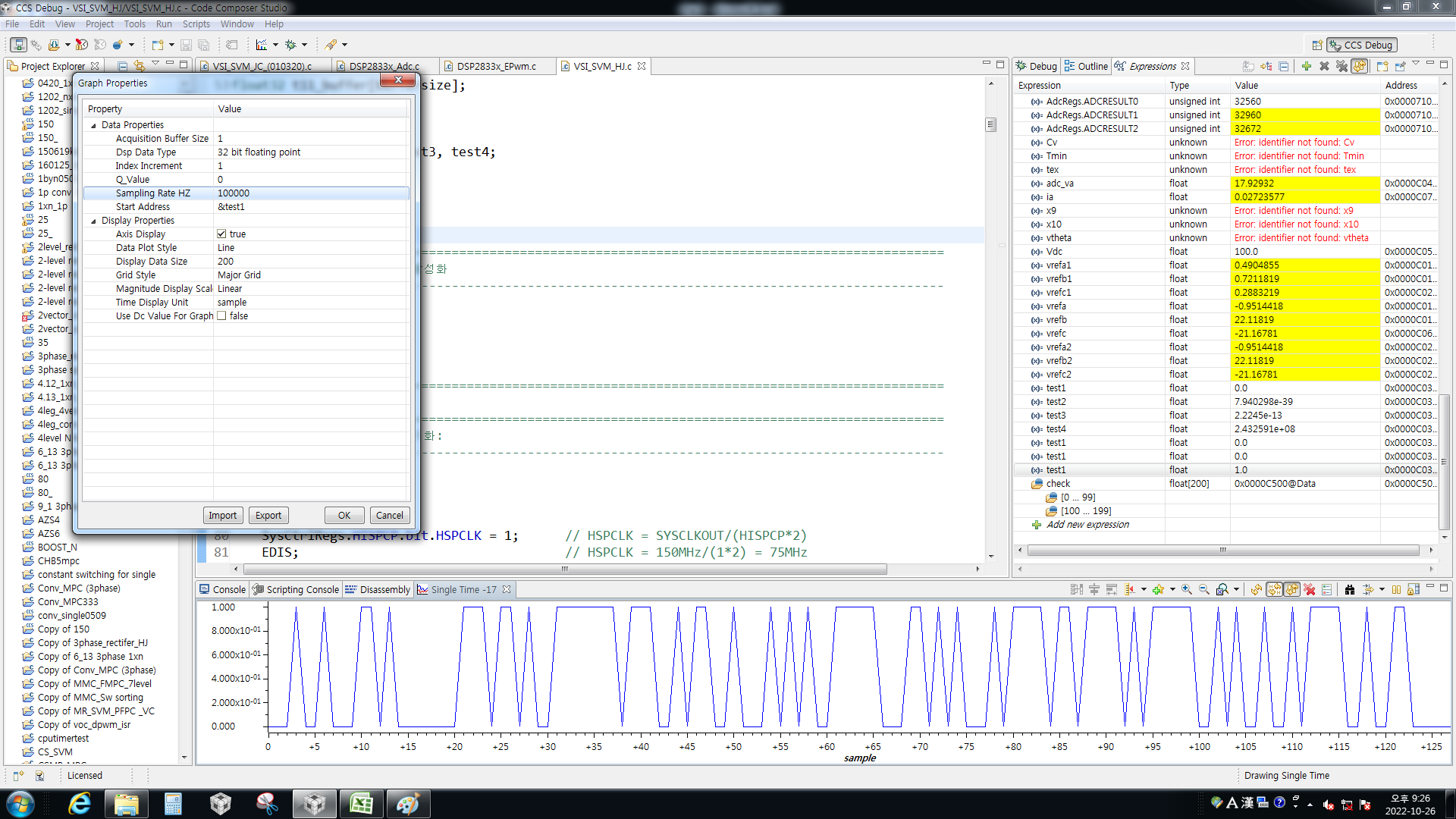

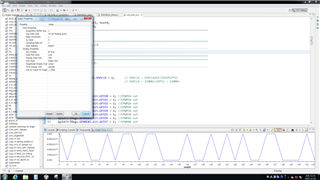

I am using DSP F28335 to control a converter.

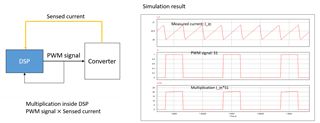

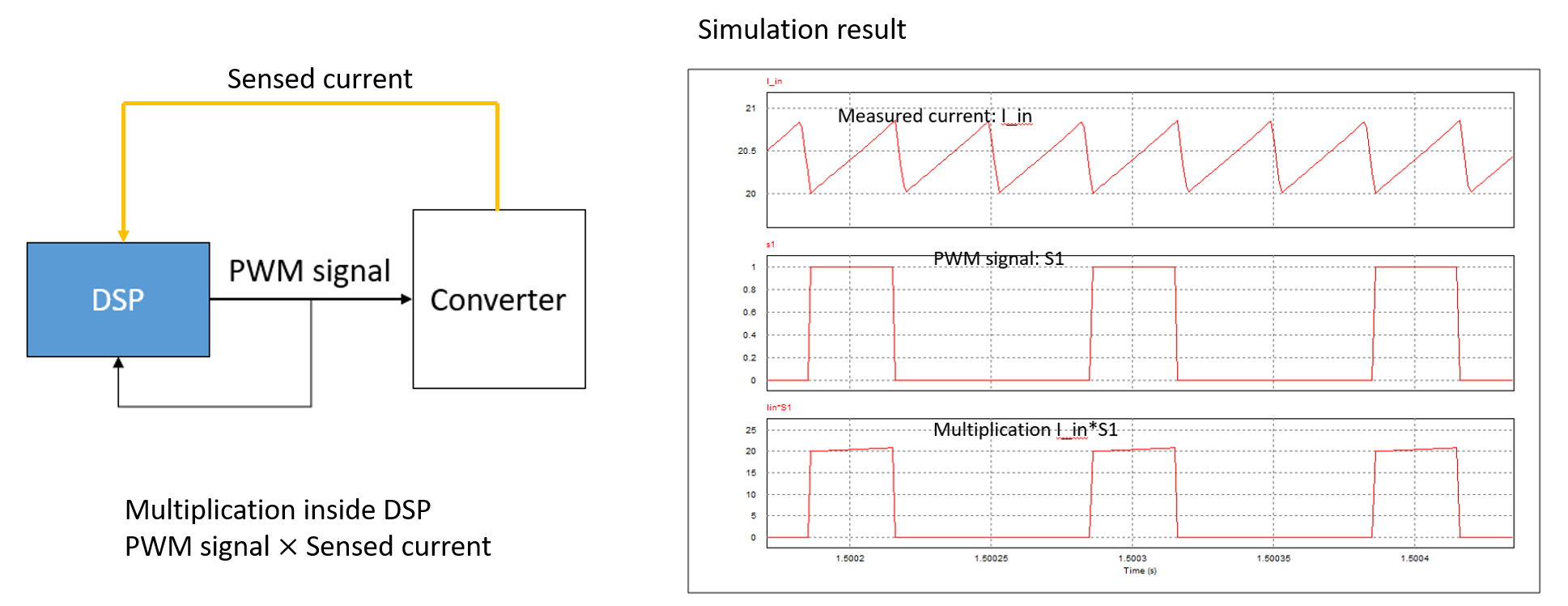

Currently, I have to use the generated PWM signal from ePWM module as a variable. I mean I need to get the multiplication between generated PWM signal and a sensed current signal.

Is there any method to get the PWM signal?

Thanks!