Other Parts Discussed in Thread: MOTORWARE

Hi team,

Currently I'm using the motorware_1_01_00_14 version. The following problems have emerged in the project: (the latest version is motorware_1_01_00_18)

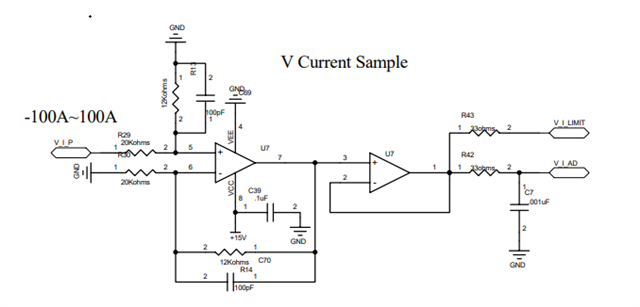

1) The rated power is 5KW, the bus voltage is 72V, the maximum peak current is 150A (using InstaSPINTm-FOC), and two current sensors are used. The problem now is that it cannot rotate when I start it. Most of them can start smoothly without load but they cannot start smoothly when they are loaded. Very rarely, they run smoothly after being loaded. Could you please analyze my issue?

2) The latest version is motorware_1_01_00_18, what is the difference between it and the motorware_1_01_00_14 that we are currently using?

3) For different power motors, we mainly modify the following parameters. Do I need to modify other parameters?

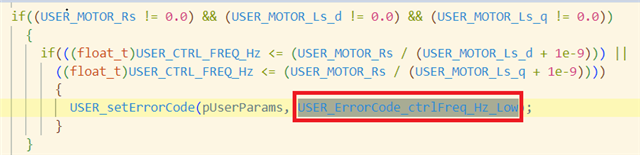

4) The motor is 20V/20W, the stator resistance is 9Ω, the inductance is 45uH, 1 pair of stages, 30,000 revolutions, the reverse electromotive force cannot be identified, and the control frequency is too low. As the frequency in the algorithm is greater than the resistance divided by the inductance and the inductance of the motor is too small, the required frequency is too high.

Kind regards,

Katherine