Hi,

I use EPWM1 interrupt at 180kHz for calculating CMPA values for SPWM generation.

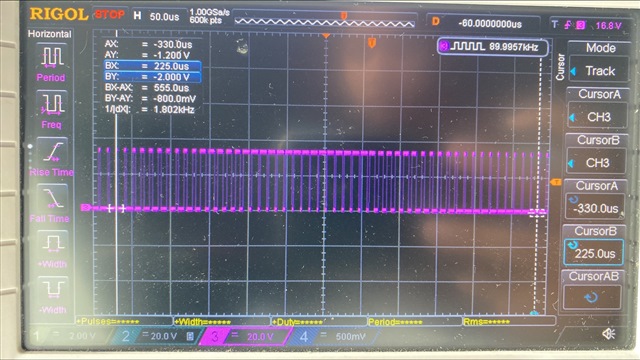

Because of such high frequency I see occasional disturbance in SPWM waveform when I have CAN ISR processing incoming messages.

I would like to know if I can move the calculations done in EPWM ISR into some other peripheral like CLA so that the processor can be freed from such a time critical and sensitive work.

Currently I trigger EPWM ISR for TBCTR = 0 and TBCTR = PERIOD, Is it possible to have the CLA be triggered for this scenario?

Please do suggest any other solutions that might be more optimized than triggering EPWM ISR at 180kHz for updating CMPA. (I cannot use DMA as the calculations need real time input from control loops)

Regards,

Rashmitha