Other Parts Discussed in Thread: CONTROLSUITE, C2000WARE-MOTORCONTROL-SDK, C2000WARE

Hi TI experts,

I want to drive a PMSM motor using C2000 microcontrollers.

I am using foc algorithm for controling the motor.

I have designed a custom board. I started this this application note:

C:\ti\controlSUITE\development_kits\DRV8312-C2-KIT_v128\PM_Sensorless

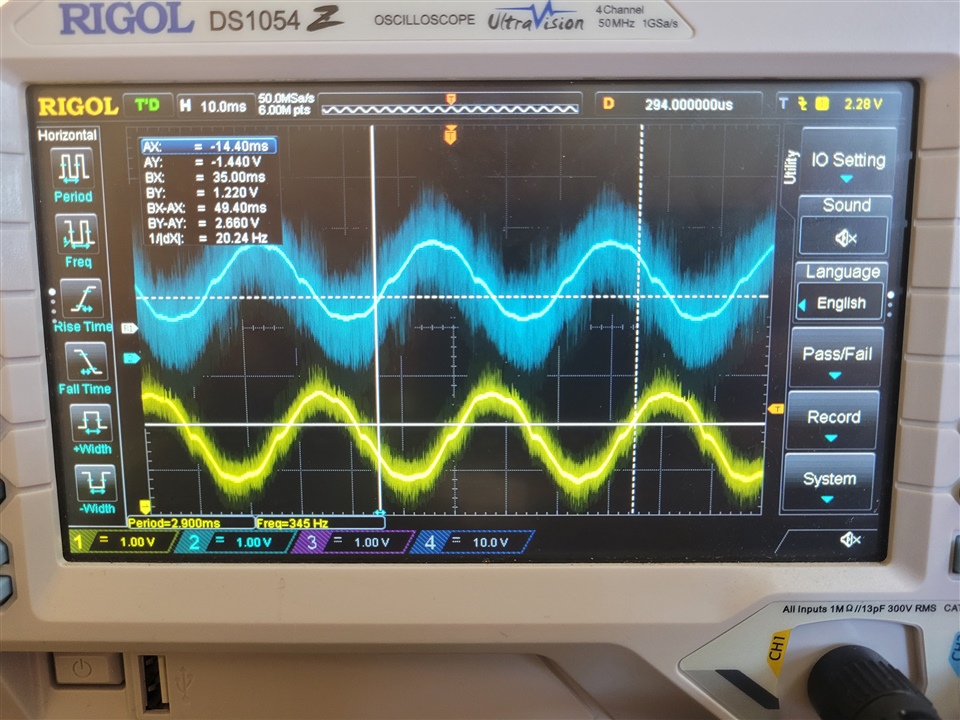

In build level 4 after tuning pid controllers’ parameters, the current waveforms of phase A & B should appear as the following image:

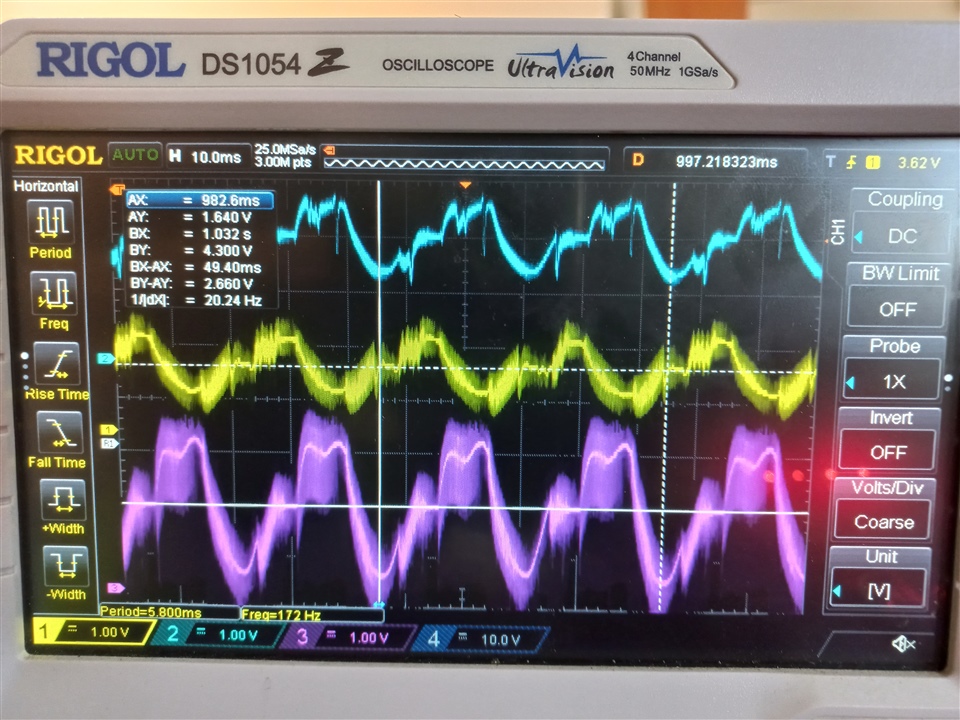

However, when I check the waveforms, they are not completely sine waves. Here is the current waveforms of phase A&B.

The blue one is current waveform of phase A (using PWMDAC), the yellow one is current waveform of phase B (using PWMDAC) and purple one is also current waveform of phase A (using scope probe on the output of current sensor).

Can I consider these wave as sine waveform? I’m afraid that I have not tuned PID controllers’ parameters (Iq, Id) correctly.

Thank you in advance.