Other Parts Discussed in Thread: TMDSHVMTRINSPIN, C2000WARE

Hi TI team,

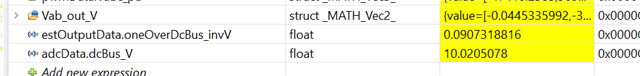

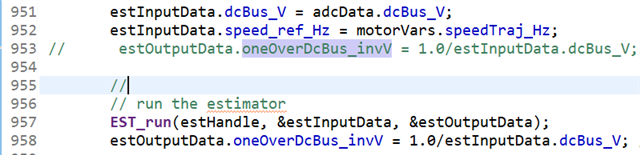

I'm debugging the motor control with TMDSHVMTRINSPIN in C2000Ware_MotorControl_SDK_4_00_00_00. However, there is an wired issue in lab4 (current close loop). The code's location will influence the value of oneOverDcBus_invV, which will jump between a very big vlue and 1/Vbus. Further, the CMPA‘s value will not a constant value anymore. If I place this code to from line953 to line958, this issue will disappear. So is there any potential issue for the EST and the next labs? Why is like that?

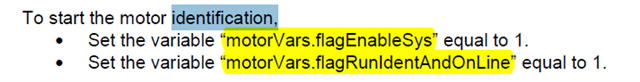

Another question is about lab5: motor ID. I have tried to start the identification, but failed. The following picture is the flag value and Ctrl/Est state. Could you please help to double check the right command to start motor ID. Looking forward to your reply! Thanks!

Best regards,

Iris Liu