Other Parts Discussed in Thread: UNIFLASH

Hi Expert,

My customer are using F28034 for mass production, there have some possibility that fail to program the F28034 by JTAG, the error report Verification failed,

actually they need to program APP code and Boot code independently, the error only occur when they program Boot code,

They program the APP code firstly and always successfully, then program Boot code, some possibility will fail.

It is not allowed to program Boot code first and then APP because there have one flash sector are shared by both Boot code and APP code,

They use a .bat file to run command which will run Uniflash to program APP code and bootloader code automatically.

![]()

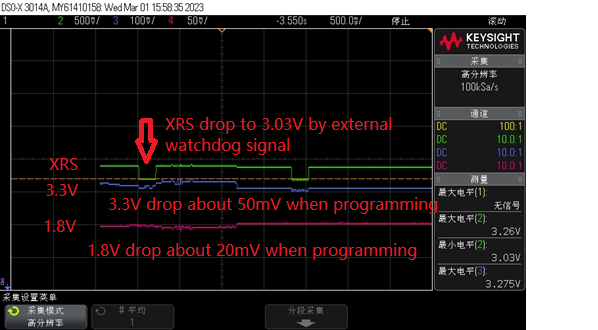

They monitor the waveform below when do programming, have a little drop but seem still at normal range.

The issue may also related to hardware of external watchdog circuit, when XRS pin is connected to external watchdog, there have a little voltage drop to about 3V as above showed, in this case, there will have possibility fail to program Boot code, but always successfully program APP code at the first time.

if they disconnect XRS pin to external watchdog and keep XRS pin stable, then always program both Boot code and APP code successfully.

Any suggestion on how to fix this issue? I will update schematic by email when get customer's schematic.