Other Parts Discussed in Thread: SFRA, UNIFLASH, C2000-GANG

Hi Team,

There's an issue from the customer need your help:

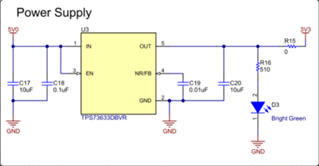

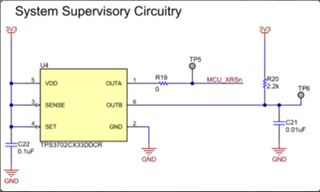

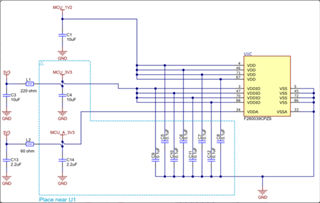

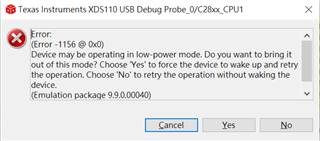

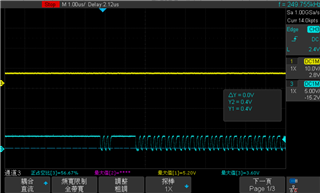

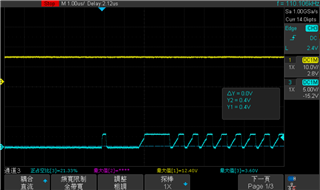

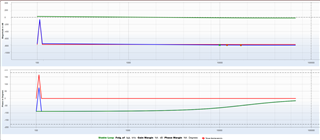

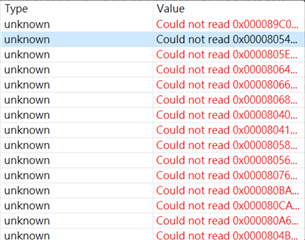

Hello, I am testing the BuckBoost routine. I use the 0039C development board to burn and then jump to the main circuit. There is no problem with the connection of CCS, but I use the XDS110 jumper to connect to the control board I designed. After the main circuit, I found that when I adjust the duty to be greater than 0.4, that is, the control board will be disconnected from the CCS when operating in equal voltage and Boost mode. I measured that the 3.3V of the control board is very stable. I would like to ask what is the problem. The picture below is the output voltage (yellow) and 3.3V (purple) on the control board when my duty is adjusted from 0.4 to 0.5

Could you help check this case?

Thanks & Regards,

Ben