Hi TI team:

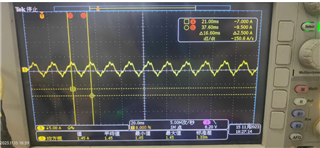

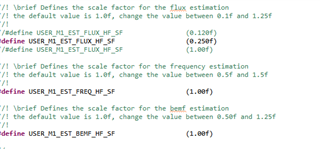

please help to confirm ,how to set the delay of sample point ot avoid the switching noise .

I am using the universal motor control lab solution to run my own board and motor.

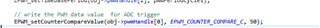

but in Level 3, the motorVars_M1.speed_Hz can not follow the motorVars_M1.speedRef_Hz.

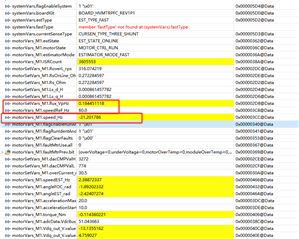

I check the current and voltage signal of ADC input ,find some switching noise.

So, I want to change the sampling point to avoiding the switching noise.

please help ,how to change . thanks a lot