Other Parts Discussed in Thread: DRV8353RS-EVM, SFRA, LAUNCHXL-F28P65X

Hi,

I am working on the Universal Motor Control Lab project, with the f28p65x LaunchPad and the DRV8353RS-EVM boards.

I follow the instructions of the SPRUJ26 user's guide

I have passed DMC_LEVEL1 up to DMC_LEVEL3 without any problem.

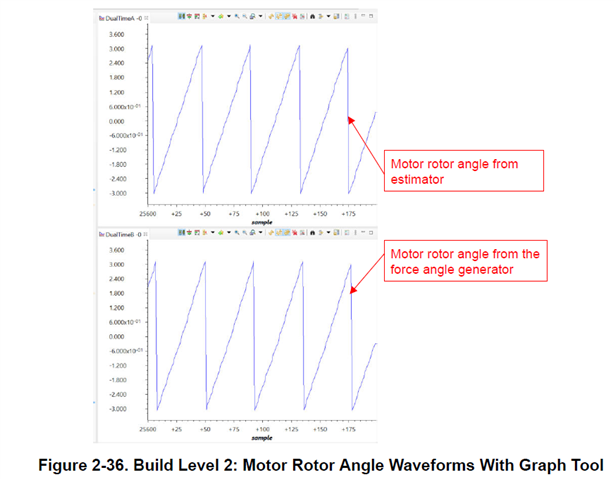

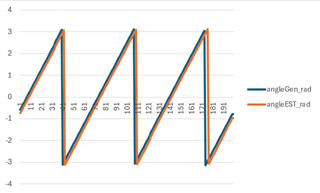

At DMC_LEVEL4 (9.b. page 84 of SPRUJ26), I have two problems.

The first one is that there is a startupFailed flag, that means I can't reach the colesd loop speed control with my motor and the rotor keeps spinning at really low speed.

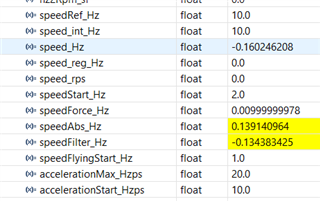

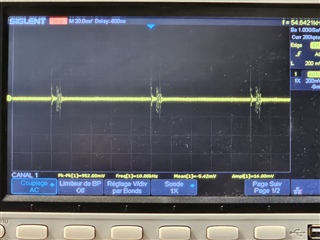

The second one is that, when the rotor keeps spinning at very low speed, there a scale factor of around 4 between the speed value that I can read (speed_Hz = 0.008 => 0.48rpm) and the physical speed (2rpm).

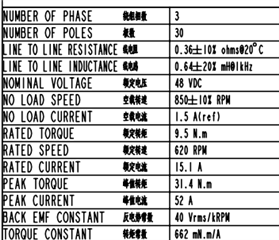

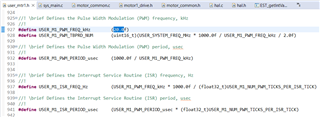

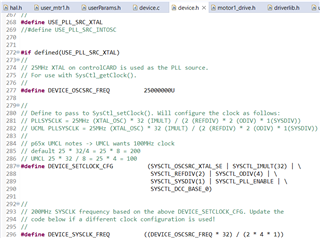

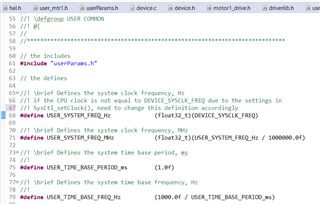

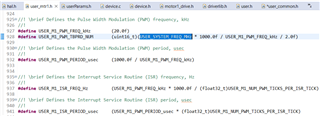

I think there is a problem in my motor parameters (in user_mtr1.h).

Do you have a user's guide that details how to set the motor parameters correctly and tune the controllers please?

Thanks a lot in advance for your help.

David