Other Parts Discussed in Thread: TIDM-DC-DC-BUCK, TIDM-02000, POWERSUITE, SFRA

Hi,

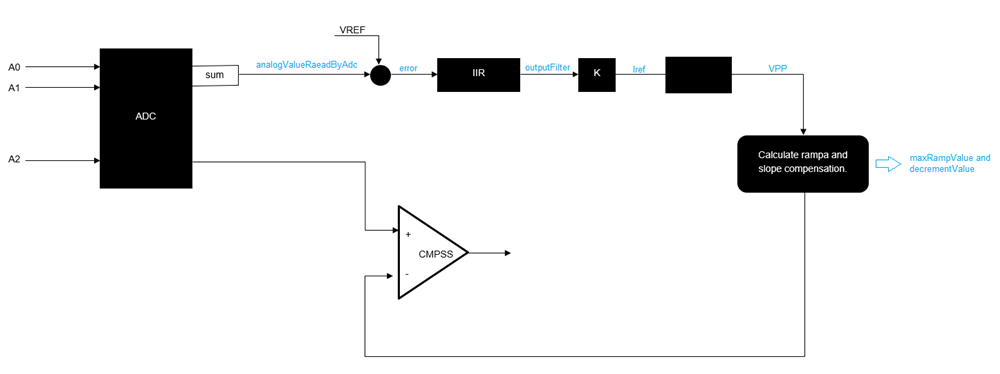

I implemented a peak current mode control with slope compensation following the documents listed below:

- Step-by-Step Design Guide for Digital Peak Current Mode Control: A Single-Chip Solution (Biricha Digital Power LTD)

- SPRABE7A: Digital Peak Current Mode Control With Slope Compensation Using the TMS320F2803x.

But I have some doubts.

I have an ePWM with Fswitching = 100KHz and every 100KHz the ADC interrupt occurs to read the analog inputs and perform the calculation of maxRampValue and decrementValue. In particular:

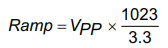

1) I calculate the error as: error = VREF - analogValueReadByAdc. Where VREF is calculated as reported in the Biricha document with the Equation 19: ![]() where ADCbits = 12 and VDAC = 3,3V.

where ADCbits = 12 and VDAC = 3,3V.

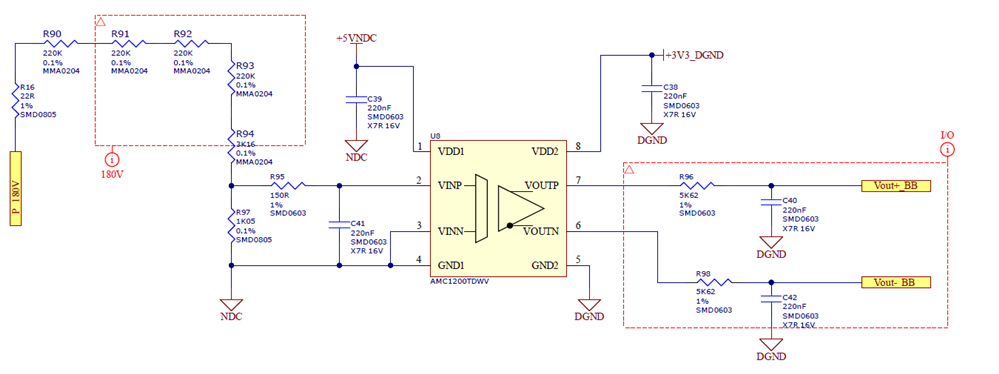

The image below, shown our feedback signal where RB = 884k21 and R1 = 1k05; in to out gain of the IC in differential mode is x8. How do we insert this value in VREF calculation?

2) The error is the input for a 2p2z filter that give me an output called outputFilter.

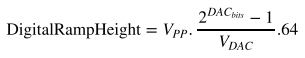

3) I multiplied the outputFilter for K calculated as reported in the SPRABE7A (pag 3 equation (1) ) ![]() where

where

- SamplingGain = 1.71

- ADCmaxV = 3.3V

- ADCbits = 12

- DACbits = 12

- DACmaxV = 3,3V

I called Iref = K * outputFilter

4) I calculate VPP as reported in the SPRABE7A (pag 7, equation (20)) ![]() where D = is the duty cycle of the ePWM read by the eCAP, Ri = 200mOhm, Ts = 10us, Vin = Iref, L0 = 200uH.

where D = is the duty cycle of the ePWM read by the eCAP, Ri = 200mOhm, Ts = 10us, Vin = Iref, L0 = 200uH.

Ri = 200mOhm is the equivalent of the transformation factor of the current sensor CT425-HSN820MR (200mV/A) that we are using.

5) I calculate the maxRampValue and the decrementValue for the ramp configuration with the equations reported below:

-

is the equation used in SPRABE71 where 1023 is the DAC bits and 3.3 is the DACmax V. This equation is the same of the Biricha document without the factor 64:

is the equation used in SPRABE71 where 1023 is the DAC bits and 3.3 is the DACmax V. This equation is the same of the Biricha document without the factor 64:  In fact, in my calculation I set ramp value with this formula: Ramp = VPP * (4095/3.3) because my DAC is 12 bits and DAC range is 3.3V.

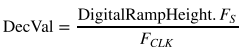

In fact, in my calculation I set ramp value with this formula: Ramp = VPP * (4095/3.3) because my DAC is 12 bits and DAC range is 3.3V.  is the equation used in Biricha document and in my application Fs = 100KHz and Fclk = 100MHz.

is the equation used in Biricha document and in my application Fs = 100KHz and Fclk = 100MHz.

Are the steps reported above correct? Are the formulas correct? Do I need to perform other calculations for peak current mode control?

I attached a schematic of my control.

Is there a way to monitor the ramp waveform? If I wont ramp value in volt, how can I do?

Thank you in advance.

Best Regards,

Debora