Other Parts Discussed in Thread: MOTORWARE, C2000WARE, TIDA-010265

Tool/software:

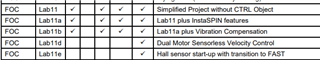

I am using the Lab2b example to add UART commands for controlling a motor. Specifically, I am implementing commands such as Rx_on to start the motor and Rx_off to stop it. I am following the HAL tutorials in Motorware for this implementation. I have added SCI functions to taken in the HAL tutorials in Motorware. The relevant files are hal.c, hal.h, and pie.c, are added or write some functions for sci which are provided below.

/cfs-file/__key/communityserver-discussions-components-files/171/7142.pie.c

Any modifies in files. Please help me anyone and also guide me. In above files any mistakes are there please modify and resend it.