Tool/software:

When I ran the code generated by psim2024, I found a strange problem. The results of single step and continuous operation of ccs program are inconsistent!

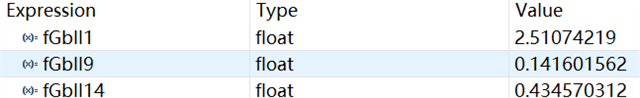

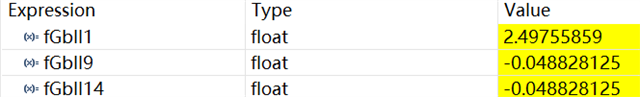

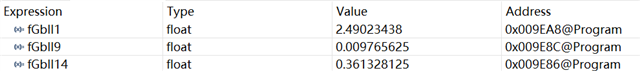

As shown in the figure, I9=(I1-2.5)*20, I14=I9 in my program, the result of continuous running is completely wrong, and the result of single step running when the breakpoint is set is correct.

ps:

1. I didn't turn on compiler optimization

2. The data is of float type, and the error is independent of the data type

3. Using the volatile keyword to modify data is also ineffective

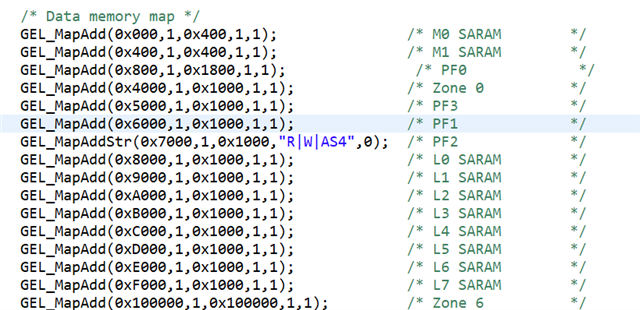

Other conditions are as follows:

Emulator: XDS100V1

Controller: f28335

ccs version: ccs6.1.3