Tool/software:

Hello all,

I'm using a Delfino F2837xD controlCard in a power converter application and I'm trying to acquire the DC voltage applied to the power converter.

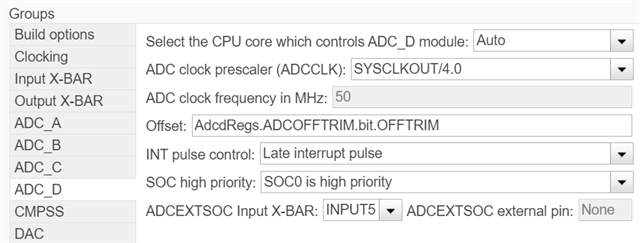

The CPU clock is set to 200 MHz, while the ADC clock is 50 MHz. I'm working on Simulink environment using the C2000 Microcontroller Blockset add-on to communicate with HW.

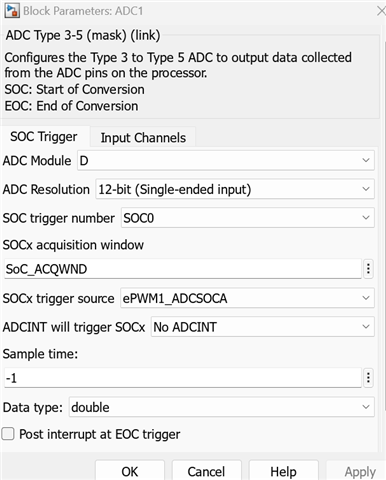

The ADC block configuration is the following:

As you can see the ADC start of conversion (SOC0) is triggered by an ePWM module at a frequency of 20kHz.

The acquisition window is the point of this discussion. I read from the documentation that the sampling acquisition time should me at least equal to the period of the ADC cycle (which is 20ns), in our case it results in a minimum acquisition window of 3. But using this value I read a voltage value with a very huge offset with respect to the operating voltage (given to the system through a DC voltage power supply). For this reason the sampling window value is set to 6, which gives the minimum offset with respect to the operating voltage.

Can anyone explain me the reason about this point?

Also, the voltage values is very noisy, as you can see from the acquisition below:

While the temperature value is better in terms of variance, with the same configuration. Is there any reason about the poor quality of the signal? I read about PPBs blocks, which should post-process the raw input signal. Are these blocks already active "by default" or should I configure them to use the feature?

Thank you a lot.

Regards,

Lorenzo