Part Number: LAUNCHXL-F280049C

Tool/software:

Hi.

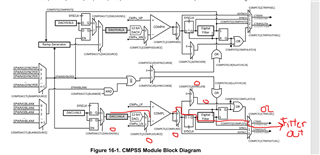

I am studying the code available for the C2000 DPS BoosterPack, and I have a question about the blanking window (I am working in open-loop VMC). This is what the CMPSS module ends up with after configuration:

-

CTRIPL goes to the EPWM X-Bar.

-

CTRIPOUTL goes to the OUTPUT X-Bar.

After configuring the trip current and the digital filtering, the code selects the EPWM1BLANK signal as the source and enables the EPWMBLANK signal.

// // Use the Blanking signal from Sync Buck EPWM to reject switching noise // CMPSS_configBlanking(BUCK_OC_CMPSS_BASE, BUCK_DRV_EPWM_NUM); CMPSS_enableBlanking(BUCK_OC_CMPSS_BASE);

Then, it configures the blanking window for the EPWM

//BUCK_DRV_EPWM_TBPRD = 499 (100MHz/200kHz -1)

//BUCK_DRV_EPWM_DC_BLANK_EARLY (5)

#define BUCK_DRV_EPWM_DC_BLANK_OFFSET ((uint16_t)BUCK_DRV_EPWM_TBPRD - BUCK_DRV_EPWM_DC_BLANK_EARLY)//494

//BUCK_EPWM_NS = 10nS

//BUCK_DRV_EPWM_DC_BLANK_EARLY = 5

#define BUCK_DRV_EPWM_DC_BLANK_LENGTH ((uint16_t)(190 / BUCK_EPWM_NS) + BUCK_DRV_EPWM_DC_BLANK_EARLY)//24

//

// BUCK_HAL_setupSyncBuckBlankingWindow - Use ePWM blanking window (filter) to:

// A) Avoid boundary conditions originating from comparator trips arriving

// near the end of ePWM cycles, and

// B) Switching noise at the start of ePWM cycles (VMC)

//

void BUCK_HAL_setupSyncBuckBlankingWindow(void)

{

EPWM_setDigitalCompareFilterInput(BUCK_DRV_EPWM_BASE,

BUCK_DRV_EPWM_DC_BLANK_SOURCE);

EPWM_setDigitalCompareBlankingEvent(BUCK_DRV_EPWM_BASE,

BUCK_DRV_EPWM_DC_BLANK_PULSE);

EPWM_setDigitalCompareWindowOffset(BUCK_DRV_EPWM_BASE,

BUCK_DRV_EPWM_DC_BLANK_OFFSET);

EPWM_setDigitalCompareWindowLength(BUCK_DRV_EPWM_BASE,

BUCK_DRV_EPWM_DC_BLANK_LENGTH);

EPWM_enableDigitalCompareBlankingWindow(BUCK_DRV_EPWM_BASE);

}

My questions are:

-

In the first code, when you configure:

-

CMPSS_Reg.COMPDACCTL.BLANKSOURCE = 0 -

CMPSS_Reg.COMPDACCTL.BLANKSOURCE = 1

Does this mean I am telling the MCU that EPWM1 will hold the trip when it occurs? Is this correct?

-

-

I don’t fully understand the configuration of the blanking window. I understand that the blanking window helps DCAEVT1/2 and DCBEVT1/2 avoid glitches, false flags (e.g., overcurrent), etc. However, how do I know if CTRIPL or CTRIPOUTL corresponds to DCAEVT1?

Checking Table 9-2, I see:

-

CMPSS1_CTRIPL = INPUTXBAR1 | CLB1_OUT12 | ADCCEVT1 -

CMPSS1_CTRIPH = ADCAEVT1

How do I determine which signal corresponds to DCAEVT1?

-

-

The blanking window configuration code selects:

-

ePWM_Reg.DCFCTL.PULSESEL = 1(Pulse select whenTBCTR = 0x00) -

ePWM_Reg.DCFOFFSET = 494 -

ePWM_Reg.DCFWINDOW = 24

How did the code select these values? How do I determine what window value and offset are suitable for my application?

-