Other Parts Discussed in Thread: SYSCONFIG, C2000WARE, LAUNCHXL-F280049C

Tool/software:

Hi,

I am currently working with the C2000(F280049C) and would like to inquire about the sampling rate capabilities of its real-time debugging features.

Specifically, I am interested in understanding the maximum achievable sampling rate for real-time monitoring and debugging using JTAG-based debugging tools such as XDS110, XDS200, and XDS560v2.

Could you provide details on:

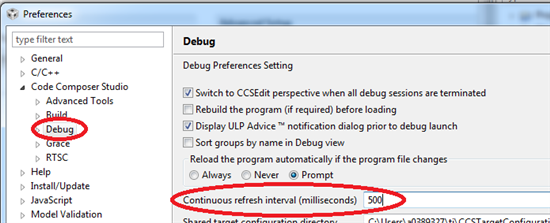

- The maximum sampling rate for real-time variable monitoring in Code Composer Studio (CCS).

- The performance differences in sampling rates between JTAG-based real-time debugging when using different debuggers (e.g., XDS110, XDS200, XDS560v2).

The background to the question is that with other companies' MCUs, real-time debugging at a few MHz can be achieved using J-Link. Since our application requires high-speed monitoring debugging of variables, it is very important that this function can be implemented in C2000.

Thanks,

Conor