Tool/software:

Hi,

We are trying to measure the DC current of an inverter with the help of low side current shunt.

Observation:

Error is less than 5% in the DC current from sensed value to clamp meter value. (Running an AC motor with V/f control having PF >0.5)

Error is almost 50% in the DC current from sensed value to clamp meter value. (Running an AC motor with V/f control having PF <0.4)

Verified: There is no problem with the motor or scaling of the controller in DC sensing. As, proper value being sensed with PF>0.5 motors and or motor under condition also measuring proper DC current.

is there any effect of PF of the AC motor in DC current sensing? How to achieve proper DC current sensing for all motors?

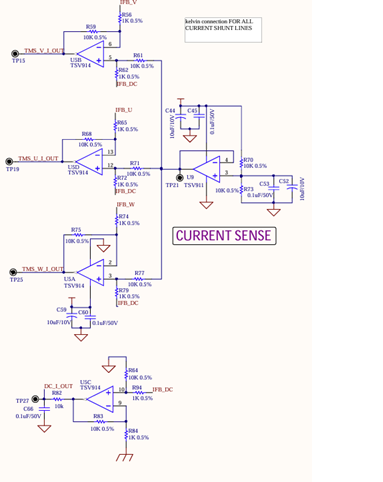

The following OPAMP circuitry has been used in the Hardware sensing.

Thanks & Regards