Other Parts Discussed in Thread: C2000WARE

Tool/software:

Hello All,

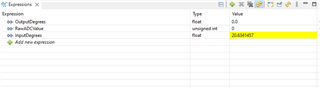

I have the following code that runs some servos and read the feedback using ADC. I am unable get the updated RawADC values in the debug session. But this problem does not occur in the older version CCS Studio 9 (C2000 Ware 4_03). So what changes need to be made to make it amenable to current version.

Here is the standalone code that runs the motors and read the ADC feedback.

#include "F28x_Project.h"

#define PCA1_SLAVE_ADDR 0x41 // First PCA9685 I2C Address

#define PCA2_SLAVE_ADDR 0x40 // Second PCA9685 I2C Address

#define MODE1_REG 0x00 // MODE1 register address

#define PRESCALE_REG 0xFE // PRESCALE register address (for PWM frequency)

#define LED0_ON_L 0x06 // First channel ON low byte

#define LED0_OFF_L 0x08 // First channel OFF low byte

// Constants

#define pulse_min 102.0f // 0.5 ms in counts

#define pulse_max 512.0f // 2.5 ms in counts

#define DEGREE_MIN 0.0f // Minimum servo angle

#define DEGREE_MAX 180.0f // Maximum servo angle

#define ADC_MAX_COUNTS 4095.0f // 12-bit ADC maximum value

#define ADC_REF_VOLTAGE 3.3f // Reference voltage of the ADC

// Calibration values for servo feedback, measured at mechanical endpoints:

//static const uint16_t adcMin = 700; // Raw ADC count at servo's minimum position

//static const uint16_t adcMax = 2500; // Raw ADC count at servo's maximum position

// Global Variables

Uint16 PWM_Frequency = 50; // Set default PWM frequency (in Hz)

Uint16 PWM_PulseWidth[20]; // Array to store pulse widths for 20 servos

Uint16 pulse_increment = 1; // Increment for adjusting PWM width

Uint16 time_index = 0;

float InputDegrees = 0.0f; // Degrees sent to Servo 20 (global variable for CCS)

float OutputDegrees = 0.0f; // Degrees sensed from Servo 20 feedback (via ADC)

Uint16 RawADCValue = 0; // Raw ADC value for debugging

float SensedPulseWidth = 0.0f; // Calculated pulse width from ADC

// ------------------------------------------------------------------------------

// Externally Adjustable Variables (Watch/we can Change in CCS)

// ------------------------------------------------------------------------------

float adcMin = 650.0f; // Raw ADC value at servo's mechanical min angle(645 is working fine)

float adcMax = 2500.0f; // Raw ADC value at servo's mechanical max angle

float pulseMin = 102.0f; // Pulse-width counts at servo min (e.g., ~0.5 ms)(these settings are specifically meant for 50 Hz)

float pulseMax = 512.0f; // Pulse-width counts at servo max (e.g., ~2.5 ms)

// We can tune these four in CCS watch window to match our system

// Function Prototypes

void I2C_Init(void);

void I2C_Write(Uint16 slave_addr, Uint16 reg, Uint16 data, Uint16 count);

void Set_Servo_PWM(Uint16 servo_num, Uint16 on_time, Uint16 off_time);

void PCA9685_Init(void);

void InitI2CGpio(void);

// --- ADC-Related Prototypes ---

void ADC_Init(void);

static void ADC_PinMuxConfig(void);

Uint16 Read_ADC(void);

float Convert_PWM_To_Degrees(float pulse_width);

void Update_OutputDegrees(void);

int main(void)

{

Uint16 servo_num, on_time, off_time;

// Uint16 pulse_min = 102; // 0.5ms for 50Hz PWM (on-time value)clock wise

// Uint16 pulse_min = 450; // 0.5ms for 50Hz PWM (on-time value)

// Uint16 pulse_max = 512; // 2.5ms for 50Hz PWM (off-time value)

// Uint16 pulse_max = 512; // 1.5ms for 50Hz PWM (off-time value)anti clockwise

// Initialize system control, GPIO, and I2C module

InitSysCtrl();

InitI2CGpio();

I2C_Init();

// Configure the pin for ADC-D1

ADC_PinMuxConfig();

// Initialize the ADC

ADC_Init();

// Initialize both PCA9685 devices (set frequency to 50Hz)

PCA9685_Init();

// Initialize pulse width for each servo at the minimum value (0.5ms)

for (servo_num = 0; servo_num < 20; servo_num++) {

PWM_PulseWidth[servo_num] = pulse_min;

}

// Main loop to continuously vary PWM signal for all 20 servos

while(1)

{

for (servo_num = 0; servo_num < 20; servo_num++) {

// Set ON time to 0 and OFF time to the current pulse width

on_time = 0;

off_time = PWM_PulseWidth[servo_num];

// Set PWM for the current servo

Set_Servo_PWM(servo_num, on_time, off_time);

// 3) If this is servo #20 (index 19), convert pulse width to degrees

// and store in an “InputDegrees” variable (for display or debugging).

if (servo_num == 19) // Servo #20

{

float servo20PulseWidth = PWM_PulseWidth[servo_num];

InputDegrees = Convert_PWM_To_Degrees(servo20PulseWidth);

// Now “InputDegrees” reflects the degrees commanded to servo #20

// Sample feedback for Servo 20 (via ADC-D1)

Update_OutputDegrees(); // This updates OutputDegrees using ADC feedback

}

// Adjust the pulse width for the next iteration

PWM_PulseWidth[servo_num] += pulse_increment;

// Reverse the increment if the pulse width goes out of bounds (between 0.5ms and 2.5ms)

if (PWM_PulseWidth[servo_num] > pulse_max || PWM_PulseWidth[servo_num] < pulse_min) {

pulse_increment = -pulse_increment;

}

}

// Add a delay to smooth out the PWM changes

DELAY_US(40000); // Delay of 10ms to simulate smooth servo movement

}

}

//------------------------------------------------------------------------------

// Function to convert PWM pulse width to degrees

//------------------------------------------------------------------------------

float Convert_PWM_To_Degrees(float pulse_width)

{

// Linear mapping from [pulse_min .. pulse_max] => [DEGREE_MIN .. DEGREE_MAX]

return DEGREE_MIN

+ ((pulse_width - pulse_min) / (pulse_max - pulse_min))

* (DEGREE_MAX - DEGREE_MIN);

}

//------------------------------------------------------------------------------

// ADC_PinMuxConfig - Configure the GPIO pin for ADC-D1

//------------------------------------------------------------------------------

static void ADC_PinMuxConfig(void)

{

// NOTE: Check the device-specific datasheet to ensure

// that GPIO30 corresponds to ADC-D1 on the package.

// For many F2837x devices, ADC-D1 can be on GPIO30.

// If our design has ADC-D1 on a different pin, modify accordingly.

EALLOW;

// Make sure the pin is configured as an analog input to the ADC:

// Typically for F2837xD:

GpioCtrlRegs.GPADIR.bit.GPIO30 = 0; // input

// Set MUX to 3 for ADC (check TRM/datasheet for correct setting)

GpioCtrlRegs.GPAMUX2.bit.GPIO30 = 3;

EDIS;

}

//------------------------------------------------------------------------------

// ADC_Init - Initialize ADC-D (12-bit, single-ended, Channel D1).

//------------------------------------------------------------------------------

void ADC_Init(void)

{

EALLOW;

// 1. Power up the ADC

// Set prescale => ADCCLK = SYSCLK / (1 + PRESCALE)

AdcdRegs.ADCCTL2.bit.PRESCALE = 6;

// 2. Set ADC mode to 12-bit resolution, single-ended

// (Pass in "ADCD" if our header defines ADC_ADCD for the module ID)

AdcSetMode(ADC_ADCD, ADC_RESOLUTION_12BIT, ADC_SIGNALMODE_SINGLE);

// 3. Set interrupt pulse at the end of conversion

AdcdRegs.ADCCTL1.bit.INTPULSEPOS = 1;

// 4. Enable ADC power

AdcdRegs.ADCCTL1.bit.ADCPWDNZ = 1;

EDIS;

// 5. Wait for ADC to power up (datasheet recommends ~1 ms)

DELAY_US(1000);

// 6. Configure SOC0

EALLOW;

// Channel Select: 1 => ADC-D1

AdcdRegs.ADCSOC0CTL.bit.CHSEL = 1;

// Sample window (ACQPS). Minimum: (resolution cycles) + overhead.

// For 12-bit, 75+ ns can suffice, 14 is a typical safe value.

AdcdRegs.ADCSOC0CTL.bit.ACQPS = 14;

// Trigger source: 5 = software trigger

AdcdRegs.ADCSOC0CTL.bit.TRIGSEL = 5;

// Select EOC0 to set INT1 flag

AdcdRegs.ADCINTSEL1N2.bit.INT1SEL = 0; // EOC0 => ADCINT1

AdcdRegs.ADCINTSEL1N2.bit.INT1E = 1; // Enable ADCINT1

// Clear any spurious interrupt flags

AdcdRegs.ADCINTFLGCLR.bit.ADCINT1 = 1;

EDIS;

}

//------------------------------------------------------------------------------

// Read_ADC - Software-trigger SOC0, wait for EOC, return ADC result

//------------------------------------------------------------------------------

Uint16 Read_ADC(void)

{

Uint16 timeout = 10000; // simple timeout to avoid endless loop

// 1. Force SOC0

EALLOW;

AdcdRegs.ADCSOCFRC1.all = 0x01; // Force SOC0

EDIS;

// 2. Wait until conversion completes or timeout

while((AdcdRegs.ADCINTFLG.bit.ADCINT1 == 0) && (timeout > 0))

{

timeout--;

}

// 3. Check for timeout

if(timeout == 0)

{

// Timeout: debug or handle error

RawADCValue = 0;

return 0;

}

// 4. Clear interrupt flag

AdcdRegs.ADCINTFLGCLR.bit.ADCINT1 = 1;

// 5. Read result

RawADCValue = AdcdResultRegs.ADCRESULT0;

return RawADCValue;

}

//------------------------------------------------------------------------------

// Update_OutputDegrees - Reads ADC and converts to "degrees"

//------------------------------------------------------------------------------

void Update_OutputDegrees(void)

{

// 1. Read the raw ADC value

RawADCValue = Read_ADC();

// 2) Convert raw ADC to a 0..1 normalized value based on servo's calibration

// (adcMin..adcMax are the servo's actual limits)

float scaledAdc = (RawADCValue - (float)adcMin) / (float)(adcMax - adcMin);

// 3) Clamp between 0..1 in case of minor overshoot or undershoot

if (scaledAdc < 0.0f) scaledAdc = 0.0f;

if (scaledAdc > 1.0f) scaledAdc = 1.0f;

// 4) Map the normalized value to the known pulse_min..pulse_max range

SensedPulseWidth = pulse_min + (scaledAdc * (pulse_max - pulse_min));

// 5) Finally, convert that pulse width to degrees

// e.g., 0.5 ms => 0°, 2.5 ms => 180° (or whatever your servo truly supports)

OutputDegrees = DEGREE_MIN

+ ((SensedPulseWidth - pulse_min) / (pulse_max - pulse_min))

* (DEGREE_MAX - DEGREE_MIN);

// Now OutputDegrees should closely reflect the servo’s actual angle

}

// Function to initialize I2C

void I2C_Init(void)

{

EALLOW;

I2caRegs.I2CMDR.all = 0x0000; // Reset I2C module

I2caRegs.I2CPSC.all = 6; // Prescaler for 200 MHz clock

I2caRegs.I2CCLKL = 145; // Low time for I2C clock (for 100 kHz)

I2caRegs.I2CCLKH = 145; // High time for I2C clock (for 100 kHz)

I2caRegs.I2CMDR.all = 0x0020; // Enable master mode

I2caRegs.I2CSTR.all = 0x0000; // Clear status register

EDIS;

}

// Function to write data to a register of the PCA9685

void I2C_Write(Uint16 slave_addr, Uint16 reg, Uint16 data, Uint16 count)

{

I2caRegs.I2CSAR.all = slave_addr; // Set slave address

I2caRegs.I2CMDR.all = 0x6E20; // Master transmit, start condition

I2caRegs.I2CCNT = count; // Set number of bytes to transmit

I2caRegs.I2CDXR.all = reg; // Register address to write to

DELAY_US(500);

// while (I2caRegs.I2CSTR.bit.ARDY == 0); // Wait until register address is sent

I2caRegs.I2CDXR.all = data; // Write the data to the register

DELAY_US(500);

// while (I2caRegs.I2CSTR.bit.ARDY == 0); // Wait until data is sent

}

// Function to set PWM for each servo

void Set_Servo_PWM(Uint16 servo_num, Uint16 on_time, Uint16 off_time)

{

Uint16 slave_addr = (servo_num < 10) ? PCA1_SLAVE_ADDR : PCA2_SLAVE_ADDR;

Uint16 channel = servo_num % 10; // Channel on the PCA device (0-9)

Uint16 on_low = (on_time & 0xFF); // Extract low byte of ON-time

Uint16 on_high = ((on_time >> 8) & 0x0F); // Extract high byte of ON-time

Uint16 off_low = (off_time & 0xFF); // Extract low byte of OFF-time

Uint16 off_high = ((off_time >> 8) & 0x0F); // Extract high byte of OFF-time

// Write ON time to the correct channel

I2C_Write(slave_addr, LED0_ON_L + 4 * channel, on_low, 2);

I2C_Write(slave_addr, LED0_ON_L + 1 + 4 * channel, on_high, 2);

// Write OFF time to the correct channel

I2C_Write(slave_addr, LED0_OFF_L + 4 * channel, off_low, 2);

I2C_Write(slave_addr, LED0_OFF_L + 1 + 4 * channel, off_high, 2);

}

// Function to initialize PCA9685 devices

void PCA9685_Init(void)

{

// Write to MODE1 register to reset both PCA devices

I2C_Write(PCA1_SLAVE_ADDR, MODE1_REG, 0x80, 2); // Reset PCA1

I2C_Write(PCA2_SLAVE_ADDR, MODE1_REG, 0x80, 2); // Reset PCA2

DELAY_US(10000); // Wait for 10 ms

// Write to MODE1 register to Sleep both PCA devices

I2C_Write(PCA1_SLAVE_ADDR, MODE1_REG, 0x10, 2); // Sleep PCA1

I2C_Write(PCA2_SLAVE_ADDR, MODE1_REG, 0x10, 2); // Sleep PCA2

DELAY_US(10000); // Wait for 10 ms

// Set PWM frequency (50Hz) by writing prescale register

I2C_Write(PCA1_SLAVE_ADDR, PRESCALE_REG, 0x79, 2); // Set 50Hz for PCA1

I2C_Write(PCA2_SLAVE_ADDR, PRESCALE_REG, 0x79, 2); // Set 50Hz for PCA2

DELAY_US(10000); // Wait for 10 ms

// Write to MODE1 register to wake up both PCA devices

I2C_Write(PCA1_SLAVE_ADDR, MODE1_REG, 0xA1, 2); // Wake up PCA1

I2C_Write(PCA2_SLAVE_ADDR, MODE1_REG, 0xA1, 2); // Wake up PCA2

DELAY_US(10000); // Wait for 10 ms

}

// Function to initialize I2C GPIOs

void InitI2CGpio(void)

{

EALLOW;

GpioCtrlRegs.GPBPUD.bit.GPIO32 = 0; // Enable pull-up on GPIO32 (SDAA)

GpioCtrlRegs.GPBPUD.bit.GPIO33 = 0; // Enable pull-up on GPIO33 (SCLA)

GpioCtrlRegs.GPBQSEL1.bit.GPIO32 = 3; // Asynchronous input GPIO32 (SDAA)

GpioCtrlRegs.GPBQSEL1.bit.GPIO33 = 3; // Asynchronous input GPIO33 (SCLA)

GpioCtrlRegs.GPBMUX1.bit.GPIO32 = 1; // Configure GPIO32 as SDAA

GpioCtrlRegs.GPBMUX1.bit.GPIO33 = 1; // Configure GPIO33 as SCLA

EDIS;

}