Part Number: TMS320F280039C

Other Parts Discussed in Thread: PMP23338

Tool/software:

Hello everyone!

I am currently researching PMP23338, and I have a few questions would like to ask you for advice:

Q1. The routine indicates: A-TASKS(executed in every 1ms), B-TASKS(executed in every 5ms). Through testing, it was found that: the local A-TASKs executed in about 10ms), B-TASKs executed in about 300ms). My understanding is that when using my own architecture to load the corresponding when performing tasks, which should be loaded strictly according to the specified time sequence(1ms/5ms),right?

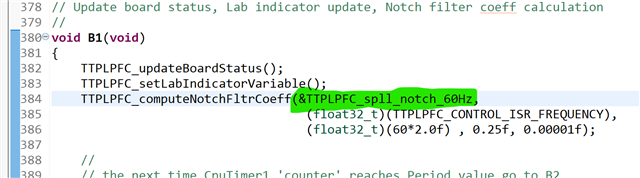

Q2. About the TTPLPFC_computeNuchFltrCoeff(), why is it not included in the initialization calculation, but we need to arrange for repeated calculations in the loop. It have any special considerations?

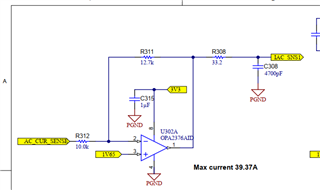

Q3. Why is * -2.0f required for TTPLPFC_read_cReturnCurrent() to read current?

Q4. Why is it necessary to perform an absolute value operation on duty( fabsf(duyt) ) in TTPLPFC_HAL_updatePWM()? Based on what considerations?

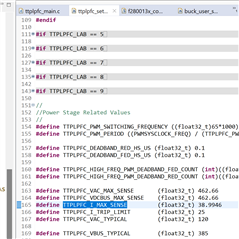

Q5. In Pre defined Symbols:

F28x_DEVICE

CPU1

LARGE_MODEL

BUILD-F28003X

What are the functions of these definitions? Additionally,

where is "__TI-EABI__ "defined (not found) and what is its specific function?