Tool/software:

Hello,

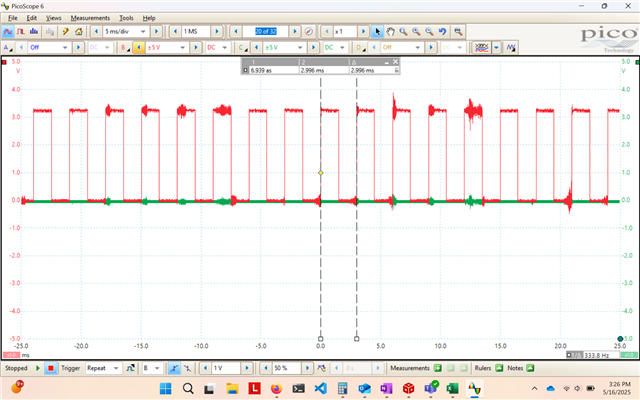

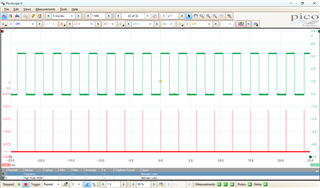

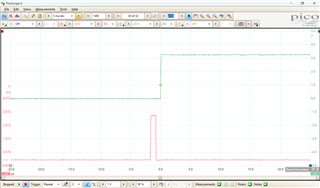

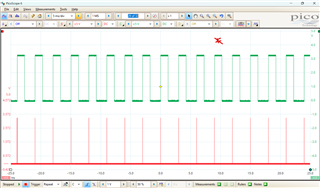

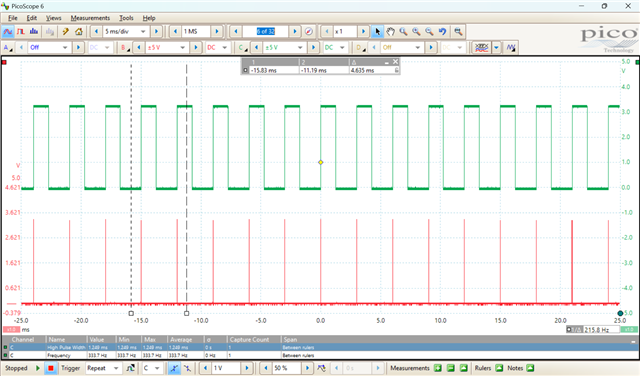

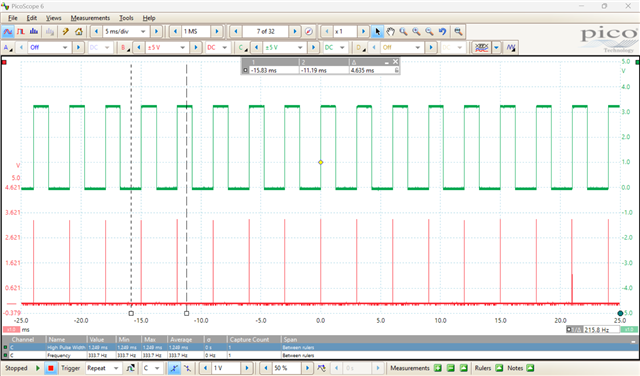

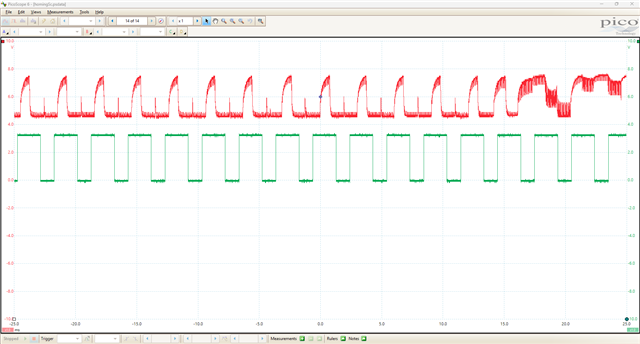

I am utilizing a 56 pin F28035 with ePWM to move a servo motor. Randomly, the servo motor will start buzzing/stuttering at certain points in its traversal. I am posting the code and a video to show what is happening. I have tried utilizing different frequencies between 50Hz to 333Hz, but the same behavior arises. For reference, the servo utilizes 333Hz. Are there any settings I should look to change or any register behavior I should look for? Normally, we use the 80 pin variant of the F28035, and buzzing does not happen as often. Thank you.

//

// Included Files

//

#include "DSP28x_Project.h" // Device Headerfile and Examples Include File

Uint16 isrCntr = 0;

Uint16 pos = 0;

Uint16 dir = 0;

__interrupt void pwm2Isr(void);

//

// Main

//

void main(void)

{

//

// Step 1. Initialize System Control:

// PLL, WatchDog, enable Peripheral Clocks

// This example function is found in the DSP2803x_SysCtrl.c file.

//

InitSysCtrl();

InitPieCtrl();

IER = 0x0000;

IFR = 0x0000;

InitPieVectTable();

InitEPwm2Gpio();

EALLOW;

GpioCtrlRegs.GPAMUX2.bit.GPIO23 = 0;

GpioCtrlRegs.GPADIR.bit.GPIO23 = 1;

GpioDataRegs.GPACLEAR.bit.GPIO23 = 1;

EDIS;

EALLOW;

SysCtrlRegs.PCLKCR0.bit.TBCLKSYNC = 0;

EDIS;

//

// Setup TBCLK

//

EPwm2Regs.TBSTS.all = 0;

EPwm2Regs.TBPHS.half.TBPHS = 0;

EPwm2Regs.TBCTR = 0;

EPwm2Regs.TBCTL.bit.CTRMODE = TB_COUNT_UP; // Count up.

EPwm2Regs.TBCTL.bit.PHSEN = TB_DISABLE; // Disable phase loading.

EPwm2Regs.TBPHS.half.TBPHS = 0x0000; // Phase is 0.

EPwm2Regs.TBCTR = 0x0000; // Clear counter.

EPwm2Regs.TBCTL.bit.HSPCLKDIV = 0; // Clock ratio to SYSCLKOUT.

EPwm2Regs.TBCTL.bit.CLKDIV = 6;

//

// Setup shadow register load on ZERO

//

EPwm2Regs.CMPCTL.bit.SHDWAMODE = CC_SHADOW;

EPwm2Regs.CMPCTL.bit.LOADAMODE = CC_CTR_ZERO;

//

// Set actions

//

EPwm2Regs.AQCTLA.bit.ZRO = AQ_SET; // Set PWM2A on Zero

EPwm2Regs.AQCTLA.bit.CAU = AQ_CLEAR; // Clear PWM2A on event A, up count

EPwm2Regs.ETSEL.bit.INTSEL = 2;

EPwm2Regs.ETPS.all = 1;

EPwm2Regs.TBCTL.bit.SYNCOSEL = 3;

EALLOW;

SysCtrlRegs.PCLKCR0.bit.TBCLKSYNC = 1;

EDIS;

EALLOW;

PieVectTable.EPWM2_INT = &pwm2Isr;

EDIS;

IER |= M_INT3;

EINT;

ERTM;

PieCtrlRegs.PIEIER3.bit.INTx2 = 1;

GpioDataRegs.GPASET.bit.GPIO23 = 1;

EPwm2Regs.ETCLR.bit.INT = 1;

EPwm2Regs.ETSEL.bit.INTEN = 1;

EPwm2Regs.TBPRD = 2815;

EPwm2Regs.CMPA.half.CMPA = 1407;

pos = 1407;

while (1) {}

}

__interrupt void pwm2Isr(void)

{

if (pos < 1642 && dir == 0)

{

EPwm2Regs.CMPA.half.CMPA = pos++;

}

else if (pos == 1642)

{

isrCntr++;

if (isrCntr > 1000)

{

isrCntr = 0;

dir = 1;

EPwm2Regs.CMPA.half.CMPA = pos--;

}

}

else if (pos > 1172 && dir == 1)

{

EPwm2Regs.CMPA.half.CMPA = pos--;

}

else if (pos == 1172)

{

isrCntr++;

if (isrCntr > 1000)

{

dir = 0;

isrCntr = 0;

}

}

EPwm2Regs.ETCLR.bit.INT = 1;

PieCtrlRegs.PIEACK.all = PIEACK_GROUP3;

}