Hello,

I have to develop a sensorless FOC with PMSM / EC motor and F28335.

I found the application note sprc128 (PMSM3_2 3-Phase Sensorless Field Oriented Control) for the older F281x series but this should be also suitable for the Delfino.

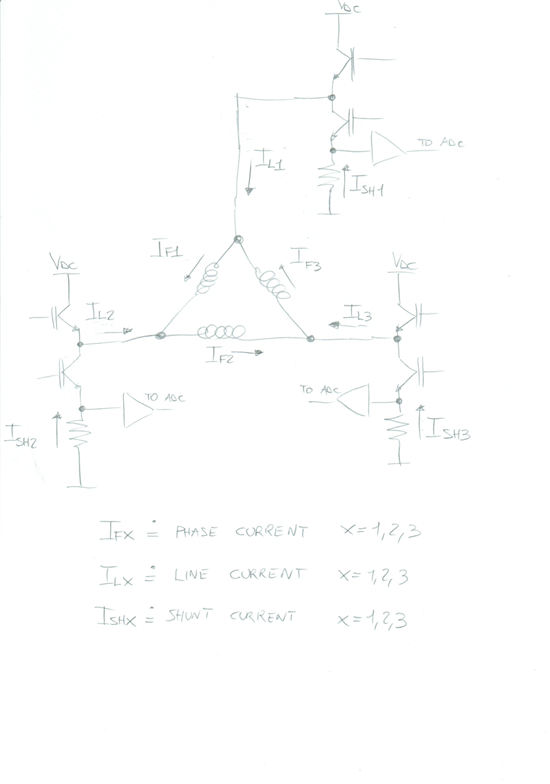

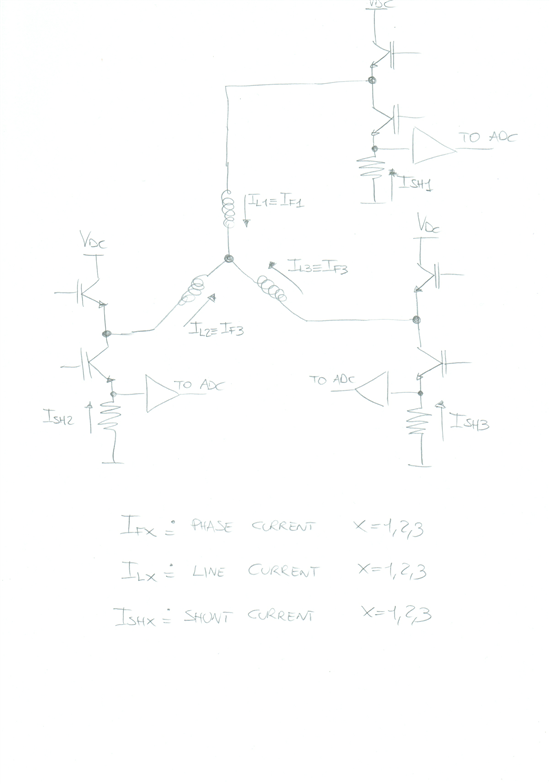

On page 5 there's a schematic where is shown, that the current of two phases is measured with only two shunts between the lower switches and ground.

This kind of low cost current measurement is what I am highly interested in. Is there anywhere an application note which describes this method detailed?

Thank you in advance for helpful hints.

Kind regards,

Robert