Other Parts Discussed in Thread: MOTORWARE, LVSERVOMTR

Tool/software:

I am using the code of dual_axis_servo_drive with LAUNCHXL-F28P55X and BOOSTXL-3PhGaN.

--------------------------------------------------BACKEMF-----------------------------------------------------------------------------

I have a motor with 93Vrms/kRPM but I need to convert it to V/Hz to set parameter M1_KB (BEMF Constant).

- If your "V" in "V/Hz" is Vrms, the value is 93.3/1000*60 = 5.598

- If your 'V' in 'V/Hz' is intended as Vpk, the value is 93.3/1000*60*sqrt(2) = 7.917

Which of the two cases?

--------------------------------------------ELECTRICAL FREQ--------------------------------------------------------------------

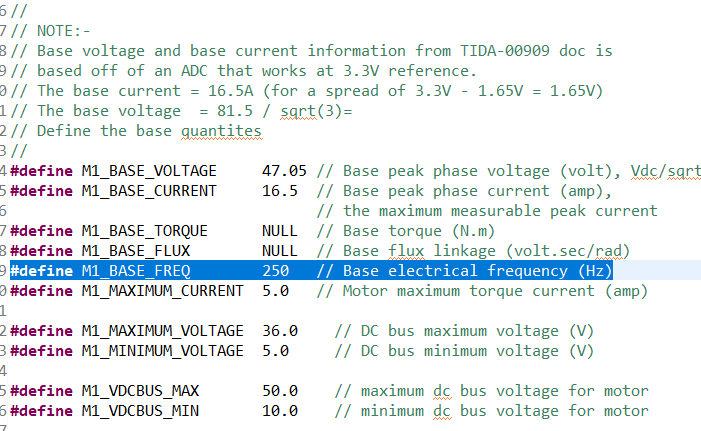

Should I change M1_BASE_FREQ in the picture below?

What does it mean?

I remember that in the motorware there were: USER_MOTOR_FREQ_LOW, USER_MOTOR_FREQ_HIGH, USER_MOTOR_FREQ_MAX, USER_MOTOR_VOLT_MIN e USER_MOTOR_VOLT_MAX

which had to be set 10% and 100%-120% of the motor rated frequency and voltage ... I cannot find these parameters any more

--------------------------------------------ENCODER LINES--------------------------------------------------------------------

It is correct to say that:

M1_ENCODER_LINES = pulses per revolution (ppr) = counts per revolut / 4

Thank you.