Other Parts Discussed in Thread: C2000WARE

Tool/software:

Hi ALL

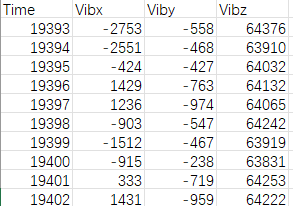

(1)I've found the data in the sample project. What do vibx, viby, and vibz represent respectively?

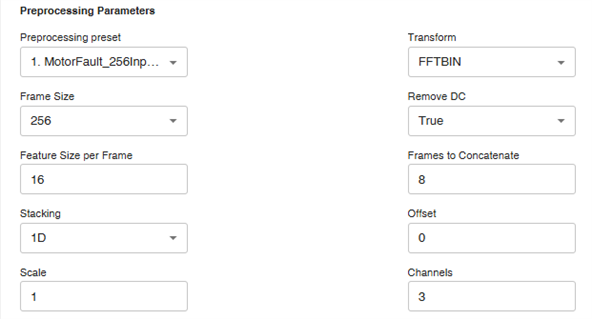

(2)I don’t fully understand these preprocessing parameter settings. If you could explain them to me, I would really appreciate it.

Best Wishes,

Xia