Tool/software:

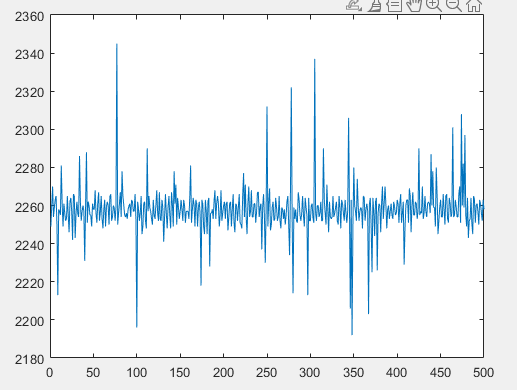

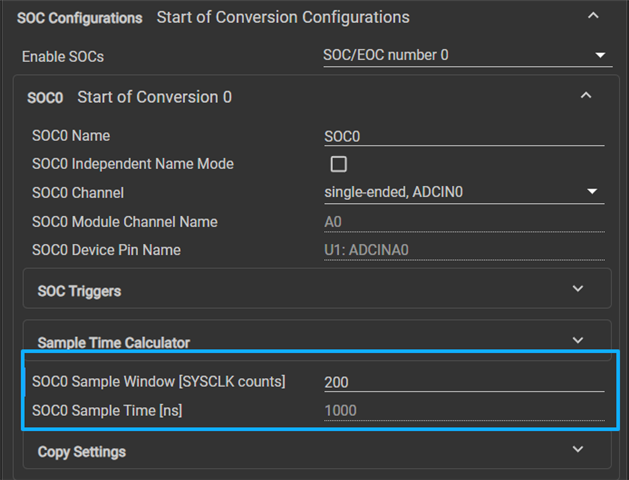

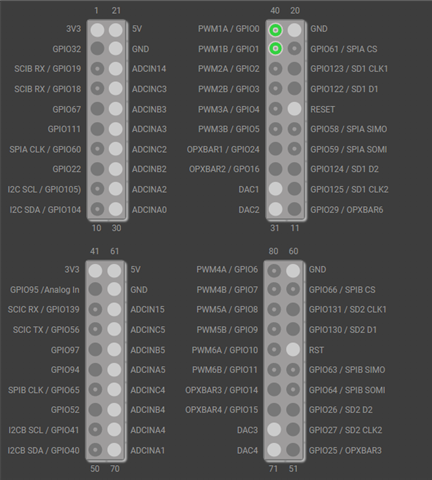

I need to perform fault diagnosis on the motor now and require a highly accurate current value. The zero position voltage measured by the current sensor is very stable, but after entering the ADC module of the f28379d, the measured current error is very large. The measured current has an error of about ±1A, that is, there is an error of 30/4096 during ADC sampling, which cannot meet the requirements of my fault diagnosis. May I ask if this is a problem with the chip or the development board?