Tool/software:

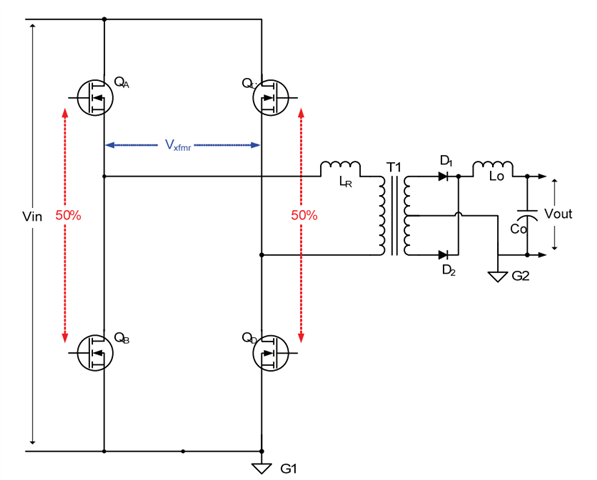

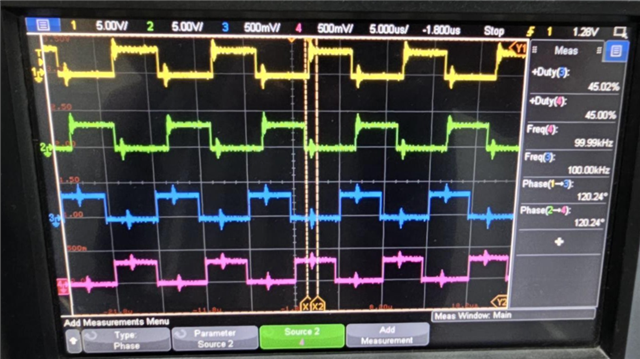

I have generated the phase-shifted PWMs of 100kHz for Phase-shifted Full bridge application.

during testing in open loop, at 100V hv input to PSFB, the phase-shifted PWM pins' frequency change to 200kHz.

This was not observed at lower voltages of 60V and 80V.

the PSFB is rated for 320V (nominal), 2.5KW.

Here are the images for reference:

PWM QA is Yellow

PWM QB is Green

PWM QC is Blue

PWM QD is Pink

PWMs at 60V:

PWM at 100V: