Hİ,

Do I make mistakes ADC settings? Can you help please. I am having problem reading a correct value of input voltage.

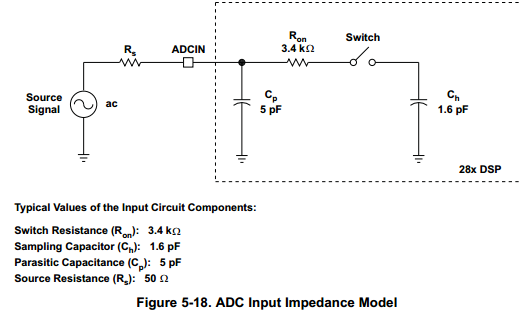

This code is built for ezdsp so it includes setup for ADC internal voltage reference, ADC_Cal is also called, ADC clock is setup, Epwm, SOC trigger, ADC control register etc, every thing is setup properly.

Since its setup for internal voltage reference i..e. REF_SEL = 0.

The AdcMirror.ADCRESULT0 is 189

With the above result, do i assume a board problem or there is something i am missing.If i connect an external voltage supply (0-3v), it may damage the board.

Any suggestions would be appreciated

below is the code only for ADC.

#include<stdio.h>

#include<stdlib.h>

#include<math.h>

#include "DSP28x_Project.h"

//------------------------------------------------------

// parametros de arranque ADC

#if (CPU_FRQ_150MHZ) // Default - 150 MHz SYSCLKOUT

#define ADC_MODCLK 0x3 // HSPCLK=SYSCLKOUT/2*ADC_MODCLK2=150/(2*3)=25.0 MHz

#endif

#if (CPU_FRQ_100MHZ)

#define ADC_MODCLK 0x2 // HSPCLK = SYSCLKOUT/2*ADC_MODCLK2 = 100/(2*2) = 25.0 MHz

#endif

#define ADC_CKPS 0x1 // ADC module clock = HSPCLK/2*ADC_CKPS=25.0MHz/(1*2)=12.5MHz

#define ADC_SHCLK 0xf // S/H width in ADC module period = 16 ADC clocks

//-------------------------------------------------------

//Definimos las variables globales

float a;

float sal_process=0;

float sp=0;

//-------------------------------------------------------

//Declaracion de las funciones.

interrupt void cpu_timer1_isr(void);

void leerADC(void);

//-------------------------------------------------------

//Inicio del programa principal

main()

{

// Step 1. Inicializacion del sistema de control:

InitSysCtrl();

// Ajuste de reloj especifico para este ejemplo:

EALLOW;

SysCtrlRegs.HISPCP.all = ADC_MODCLK; // HSPCLK = SYSCLKOUT/ADC_MODCLK

EDIS;

// Step 2.

//Borrar todas las alarmas e inicializar la tabla PIE vector:

DINT;

// Initialize the PIE control registers to their default state.

InitPieCtrl();

// Disable CPU interrupts and clear all CPU interrupt flags:

IER = 0x0000;

IFR = 0x0000;

// Inicialización de la tabla de vectores del móduloPIE

InitPieVectTable();

//Configuración del módulo ADC

InitAdc();

// Specific ADC setup for this example:

AdcRegs.ADCTRL1.bit.ACQ_PS = ADC_SHCLK;

AdcRegs.ADCTRL3.bit.ADCCLKPS = ADC_CKPS;

AdcRegs.ADCMAXCONV.all= 0x1;

AdcRegs.ADCTRL1.bit.SEQ_CASC = 0x1; // 1 Cascaded mode

AdcRegs.ADCTRL1.bit.CONT_RUN = 0x1; // Setup continuous run

AdcRegs.ADCCHSELSEQ1.bit.CONV00 = 0x0; // Setup ADCINA0 as 1st SEQ1

AdcRegs.ADCCHSELSEQ1.bit.CONV01 = 0x1; // Setup ADCINA1 as 2nd SEQ1

// configuro GPIO(64-87) como GPIO outputs.

EALLOW;

GpioCtrlRegs.GPCMUX1.all = 0x00000000;

GpioCtrlRegs.GPCDIR.all = 0xFFFFFFFF;

EDIS;

// ISR functions found within this file.

EALLOW; // Esto es necesario para escribir a registros EALLOW protegidas

PieVectTable.XINT13 = &cpu_timer1_isr;

EDIS; // Esto es necesario para desactivar escribir EALLOW registros protegidas

// Inicializar el dispositivo periférico. Esta se

// Encuentra en DSP2833x_CpuTimers.c

InitCpuTimers();

// Configurar la CPU-Timer 1, para interrumpir cada segundo:

// 150MHz CPU Freq, 2 segundo período (en uSeconds)

ConfigCpuTimer(&CpuTimer1, 150,1000000);

CpuTimer1Regs.TCR.all = 0x4001; // Use write-only instruction to set TSS bit = 0

// Step 5. User specific code, enable interrupts:

// Habilitar CPU INT13 que está conectado a la CPU-Timer 1.

IER |= M_INT13;

// Habilitar interrupciones globales y la mayor prioridad en tiempo real de los eventos de depuración:

EINT; // Habilitar la interrupción INTM Global

ERTM; // Habilitar DBGM Global interrupción en tiempo real

for(;;);

}

interrupt void cpu_timer1_isr(void)

{ unsigned int a_int,aux1;

float output_pid;

leerADC();

output_pid=sal_process;

if(output_pid>100)

output_pid=100;

if(output_pid<0)

output_pid=0;

a= (output_pid * 65535)/100;

a_int= floor(a+0.5);

GpioDataRegs.GPCDAT.bit.GPIO76 = 1;

GpioDataRegs.GPCDAT.bit.GPIO73 = 0; // coloco en bajo MLBYTE para leer '8 LSB'

GpioDataRegs.GPCDAT.bit.GPIO74 = 0; // coloco en bajo WR(negada) para cargar los '8 LSB'

// en el DAC

// Cargo los bits menos significativos GPIO

aux1= a_int;

GpioDataRegs.GPCDAT.bit.GPIO64= aux1 & 0x0001;

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO65= aux1 & 0x0001;

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO67= aux1 & 0x0001;

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO68= aux1 & 0x0001;

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO69= aux1 & 0x0001;

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO70= aux1 & 0x0001;

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO71= aux1 & 0x0001;

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO72= aux1 & 0x0001;

DELAY_US(1L);

GpioDataRegs.GPCDAT.bit.GPIO74 = 1; // coloco en alto WR(negada)

// en el DAC

GpioDataRegs.GPCDAT.bit.GPIO73 = 1; // coloco en bajo MLBYTE para leer '8 MSB'

GpioDataRegs.GPCDAT.bit.GPIO74 = 0; // coloco en bajo WR(negada) para cargar los '8 MSB'

// en el DAC

// Cargar los bits mas significativos GPIO

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO64= aux1 & 0x0001;

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO65= aux1 & 0x0001;

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO67= aux1 & 0x0001;

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO68= aux1 & 0x0001;

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO69= aux1 & 0x0001;

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO70= aux1 & 0x0001;

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO71= aux1 & 0x0001;

aux1= aux1 >> 1;

GpioDataRegs.GPCDAT.bit.GPIO72= aux1 & 0x0001;

DELAY_US(10L);

GpioDataRegs.GPCDAT.bit.GPIO74 = 1; // coloco en alto WR(negada)

// en el DAC

GpioDataRegs.GPCDAT.bit.GPIO76 = 0; // llevo LD a bajo para covertir

DELAY_US(1L);

GpioDataRegs.GPCDAT.bit.GPIO76 = 1; // retorno a alto para finalizar la conversion

// The CPU acknowledges the interrupt.

EDIS;

}

void leerADC()

{

float inadc1=0, inadc2=0;

AdcRegs.ADCTRL2.bit.RST_SEQ1 = 0x1;

AdcRegs.ADCTRL2.bit.SOC_SEQ1 = 1; // Start ADC conversion

inadc1 = AdcMirror.ADCRESULT0;

inadc2 = AdcMirror.ADCRESULT1;

sal_process=(inadc1*100)/4096;

sp=(inadc2*100)/4096;

AdcRegs.ADCTRL2.bit.RST_SEQ1 = 0x1;

}

//===========================================================================

// No more.

//===========================================================================