Hi,

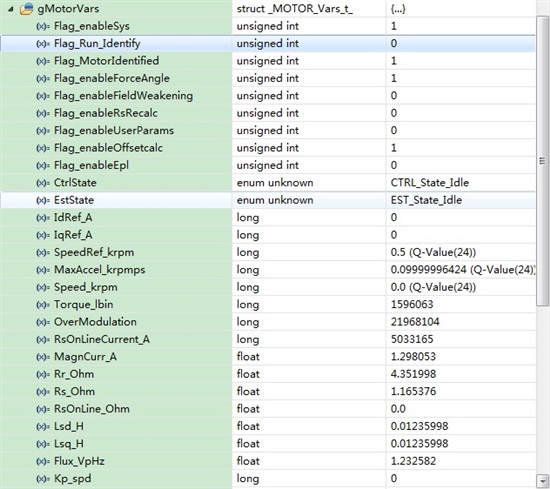

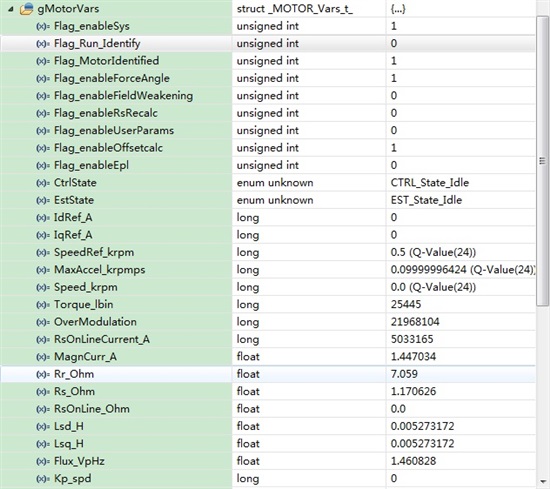

I'm using HVKIT_REV1P1 drive my ACIM,running the proj_lab2b.The estimation of all parameters have passed and success.Now I set gMotorVars.Flag_Run_Identify & gMotorVars.Flag_enableSys bits,my motor spin with about 2HZ,about 120RPM;Here is my questions:

1,reference the user's guide,I change the gMotorVars.SpeedRef_krpm,my motor speed not change,the initial value of gMotorVars.SpeedRef_krpm is 0.1,when i change it to 0.5,the motor speed not change,when i change it to 1.0,the motor speed start change,spin faster a little.

2,reference the user's guide,the gMotorVars.Speed_krpm is the estimate speed,when my motor spin at 2HZ,the gMotorVars.Speed_krpm value about 0.6,why?

3,when i using the spinsta-foc drive the ACIM,Need to pay attention to what?

Thanks!