Hi,

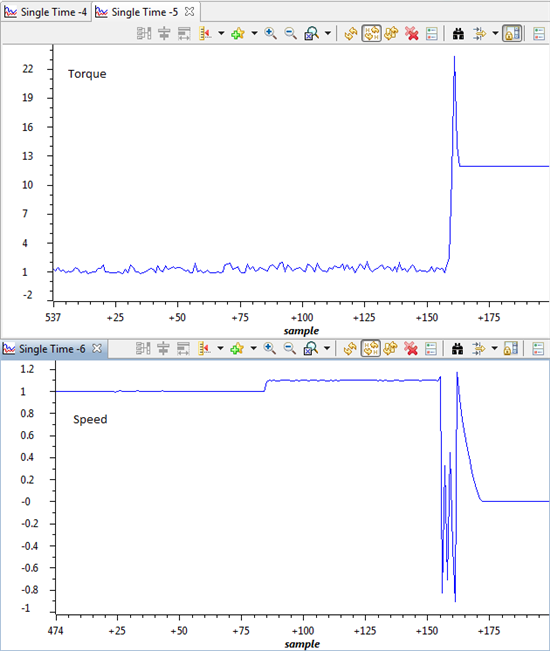

I am running the InstaSPIN-MOTION project "proj_lab12" that came with Motorware on a custom hardware. I am running a 5krpm 22 pole motor with 2000 count incremental encoder. The system seems to perform pretty well in the speed range of 0 to 1.1krpm. But, every time I increase the speed reference beyond that, the system goes unstable and begins to rotate in the reverse direction and starts oscillating.

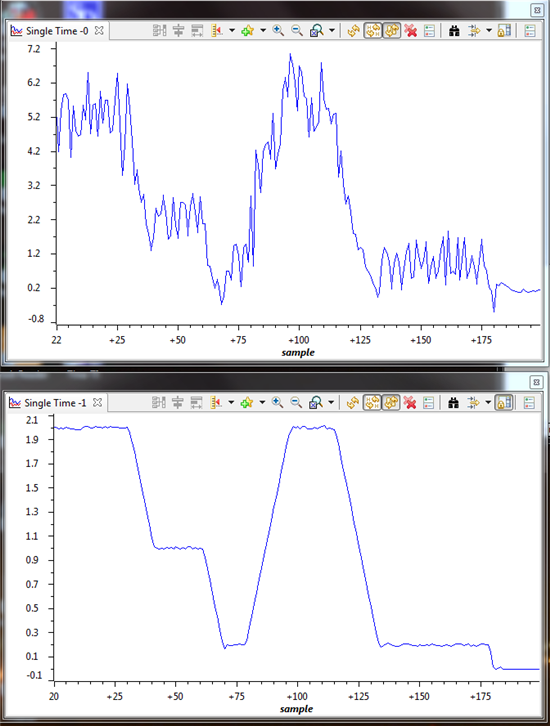

Here is a graph of "SpeedQEP_krpm" when the event occurs:

I have the "USER_IQ_FULL_SCALE_FREQ_Hz" at 1100, so I am sure that is not the issue. The encoder is rated for reliable output till 10krpm, so that doesn't seem to be the issue either.

Does this have anything to do with the SpinTAC bandwidth?

I would appreciate any ideas that might explain this behavior and help in fixing it.

Thanks,

Tamil