Good afternoon,

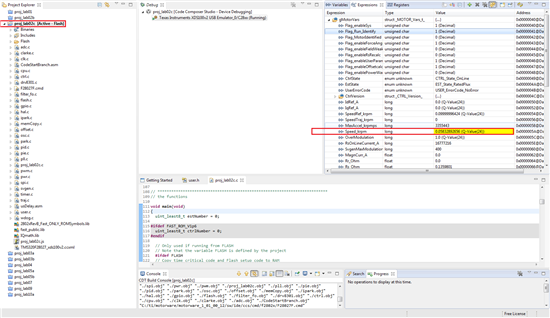

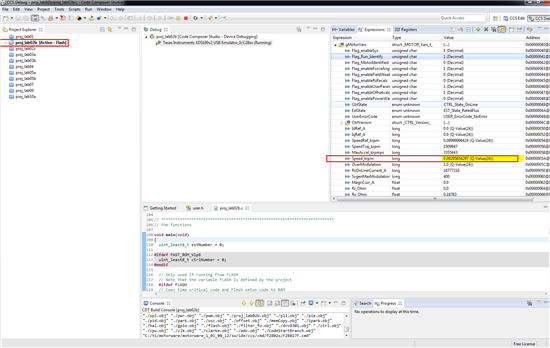

We have been trying to identify a motor for some time without success. This motor was designed with low inductance but we have not measured it independently. After much fiddling with the user.h file and the accompanying spreadsheet we finally got the identification to finish. Unfortunately the inductance values seem wrong and the motor doesn't spin neither in the identification nor current controller.

The inductance values fall within a small range spread apart several orders of magnitude. Sometimes we have 1E-9 magnitudes and others 1E-4. Either way the motor never spins when on the ramp up, with one weird exception. During the flux estimation the motor spins smoothly without any noise and as intended. During the rest of the identifications the motor acts glitchy and a bit chaotically, not spinning.

We have tried increasing the RES_EST_CURRENT and well as the USER_MOTOR_MAX_CURRENT. We don't have the load attached yet, just the motor inertia.

We have changed some of the files according to the changes in the attached excel.

2577.motorware_selecting_user_variables_gamma.xlsx

The user.h is the one attached.

We also have some previous changes according to this thread, but we think it is not a problem since the place where the adc values gets plugged does not exist in project2c. We are using a lauchpadXL with the boosterXL driver.

http://e2e.ti.com/support/microcontrollers/c2000/f/902/t/329620.aspx

Some times when we are adjusting values we also get R_OVER_L invalid errors and we must scale down to 100instead of the defaults 300, which is strange.

We also get USER_ErrorCode_ctrlFreq_Hz_Low when we make some adjustments. What is this about?

Thanks

Paulo Neves