Motor type= PMSM (Hub-Motor) Stator resistance(Phase to Phase)= 324mOhms Stator inductance(Phase to Phase)= 330uH Permanent magnet Flux= 0.12 V/Hz Pole pairs (Poles/2)= 10 Gear Ratio= 1:4.3 DC BUS= 36V Rated current= 7A Maximum current= 15A Rated Speed= 185*GearRatio RPM Maximum speed= 285*GearRatio RPM Rated Torque= 13N.m MAximum Torque= 28N.m Shape of back-EMF= Sinusoidal

Hi

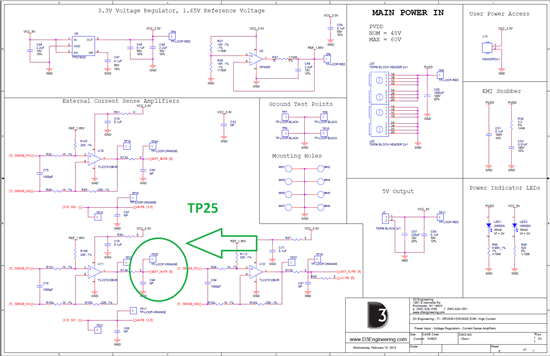

I am Julio Hernandez from a Dutch company of embedded systems; I am in charge of the motor control for one project; we decided to use the TMS320F28062F, which includes INSTASPIN-FOC. We bought a DRV3801 evaluation module for verify the performance with our motor (the parameters from the motor are attached). I measured the parameters using the InstaSpin reference manual and I compared it with the estimation of the Lab2a of Instaspin and just the Inductance was not the same (my measure with a RCL meter at 100 Hz= 330uH phase to phase; InstaSpin estimator= 320uH phase to neutral).

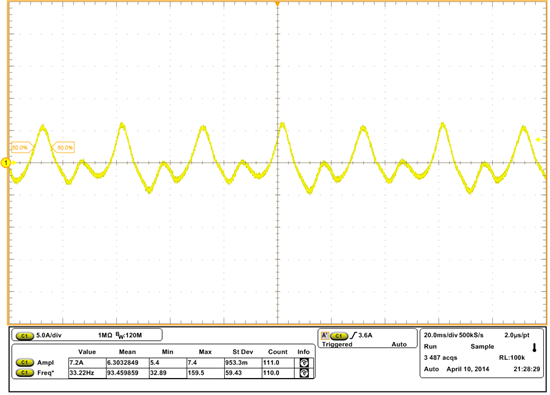

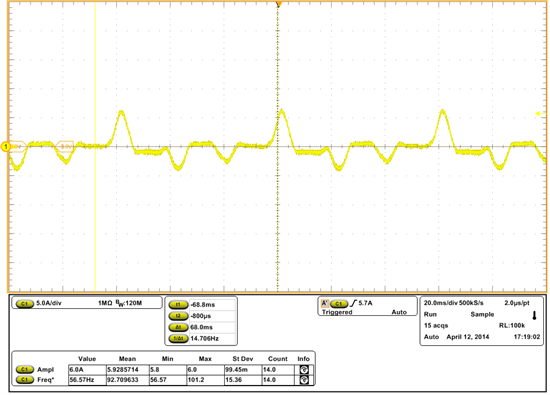

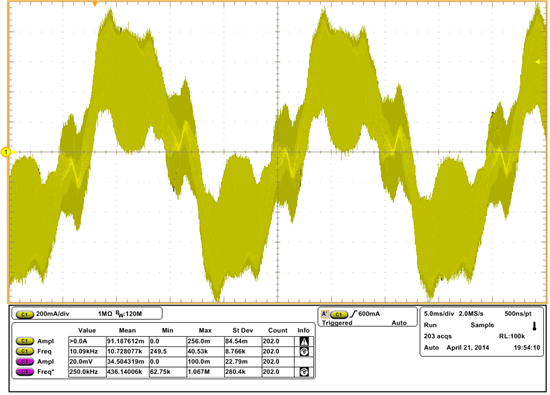

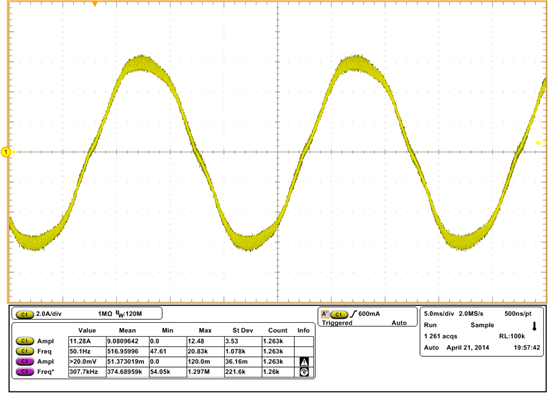

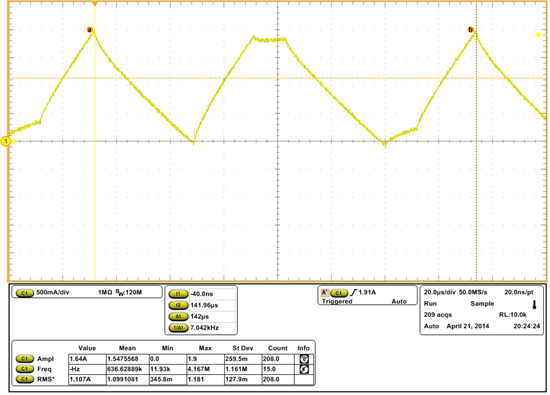

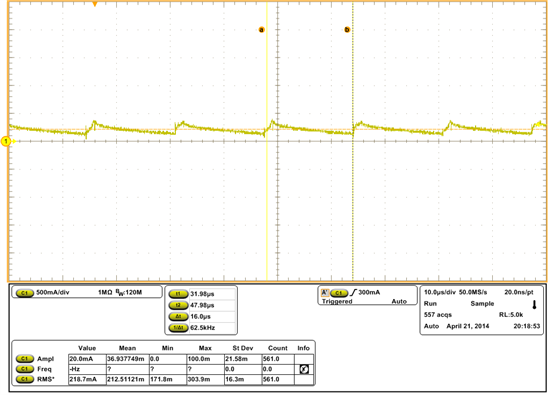

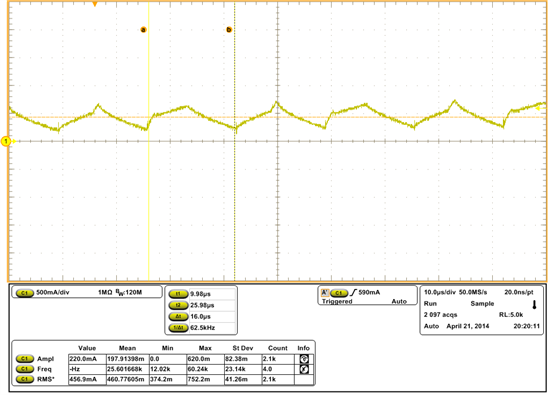

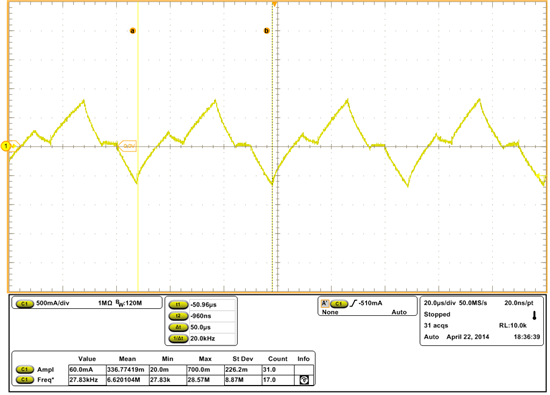

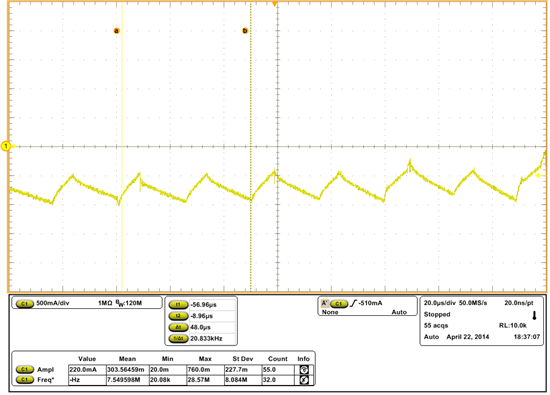

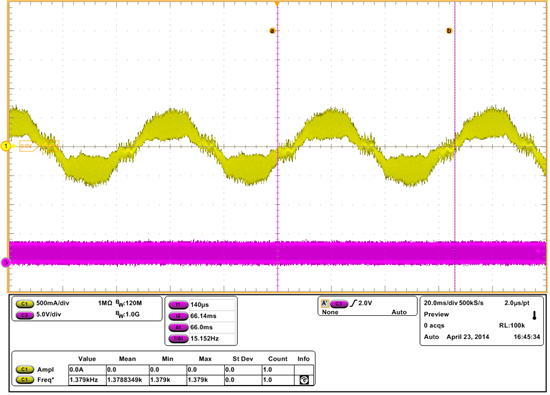

We want to use a PWM signal of 20kHz and a control loop of 10kHz, I configured the user.h file (the parameters are attached) and after some tests the rotor started to spin. The phase current U is showed below; the back EMF of the motor is sinusoidal, so I was expecting a phase current with a sinusoidal shape, but it did not.

I was trying to tune the PI controllers of the Lab5a and Lab5b in order to obtain the sinusoidal shape, but I did not have success. I think, the shape is caused because the magnetic saturation of the machine; I verified the PI controller for the d current (Id) and I found that the parameters are the same as the PI controller for q current, is it correct?.

What do you recommend to do for the next step?

Figure 1. Phase current U, the speed control is set at 100 RPM, no load applied

Figure 2. Phase current U, the speed control is set at 200 RPM, no load applied

Figure 3. Phase current U, the speed control is set at 400 RPM, no load applied

Figure 4. Phase current U, the speed control is set at 400 RPM, load applied