Hi,

now that the compiler has been updated I'm working through the labs again with our dental motor.

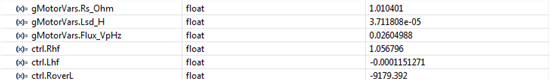

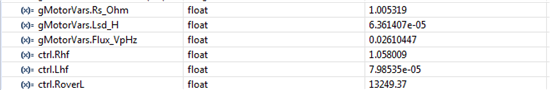

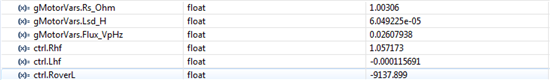

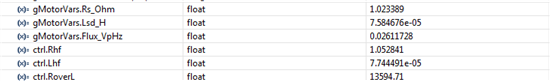

In lab5b I get very little torque before stalling the motor at low rpm (300) so I figured I would try higher rpm to see if it performs better.

Indeed at 5000 rpm I get some 80-90% of what I would expect ie 20 mNm.

But I noticed that the rpm as calculated by the InstaSPIN is different from what our dynamometer shows. Dynamo meter consistently show values that are about 10% smaller that what I set for speed ref or what InstaSpin estimates.

Moreover when I load the motor the actual speed of the motor decreases as evidenced by the dyno but InstaSpin thinks the speed is at ref value and thus will not try to compesate (fully) for the increased load.

What can be the cause?

How can this be?

I thought the 'commutation' ie inverse park is based on the rotor angle and thus I would have expected that this needs to be correct for the motor to run but now it seems like there is discrepancy somewhere...

I can't find a description how the rotor angle is calculated, I assume it is some sort of arctan of the measure back emf in the alfa/beta space, right? Is this spelled out somewhere?

br Kusti