Hi all,

I am implementing a PFC using a C2000 Launchpad, already have the system working to a fashion but I need to improve the algorithm, then increase the PWM and sampling frequency. My original target was 60kHz, but due to me using C and not assembly, the max PWM rate is 25kHz. This produces a very noisy current and input waveform (images below show the current traces). The PI loops are not tuned fully either yet, but wanted to focus on the PWM frequency first.

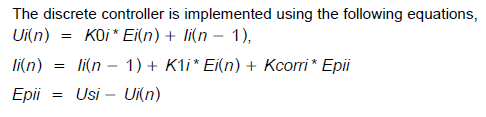

I am using various sources and on my third 3rd algorithm to see which works best, allowing me to increase the PWM and sampling rate. Want to construct an algorithm from the spra902.pdf Application Note by Shamin Choudhury. However I am having trouble understanding where 1 particular term is derived. The equations are copied below, and from page 10 of the document, which can be found here

The term Usi is the one I am unsure about, as read the report I am struggling to see the difference between Ui(n) and Usi. So unsure how Usi is derived?

Images below: First one shows the start condition no PFC in operation and the second one shows the PFC in operation. The current waveform (top) and the input voltage waveform after the bridge rectifier (bottom). A basic current transformer and resistor was used to monitor the current, as no proper oscilloscope probe was to hand.

Thanks in advance,

Ant