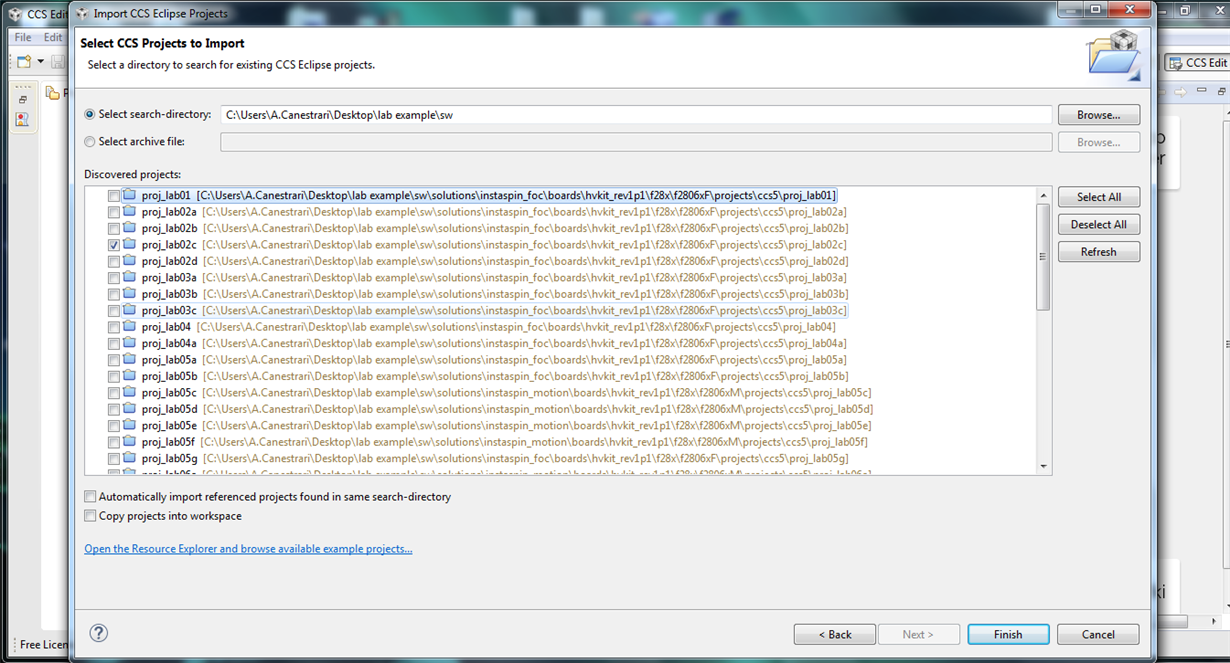

the gui InstaSPIN_MOTION_F2806xM can not detect the parameters of the engine and during the stage where should run only vibrates and emits a hiss, then I tried with projects in particular with proj_lab02a I found with the suggestions of the various posts that I read in the forum

(C: \ texasbldc\motorware_1_01_00_13\sw\solutions\instaspin_foc\boards\drv8301kit_revD\f28x\f2806xF\projects\ccs5\proj_lab02a),

but even here I could not even move it like before, I have just a vibration and a hiss even stronger.

I tried to edit the various parameters of the file header user.h following the suggestions of the various forum posts and even those in the guides of the kit, but the result does not change, for completeness I insert it below

/cfs-file/__key/communityserver-discussions-components-files/171/3443.35232.user.h

I hope that some of you know me out of this block otherwise I do not know what to do and what it parameter set.

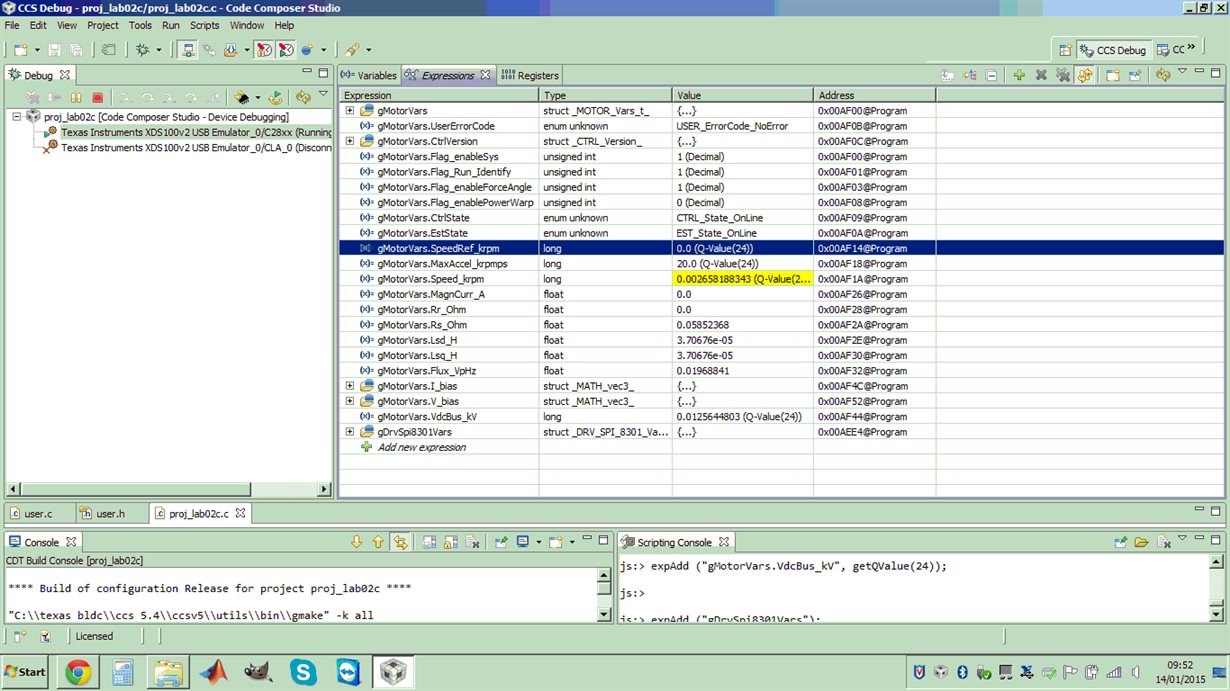

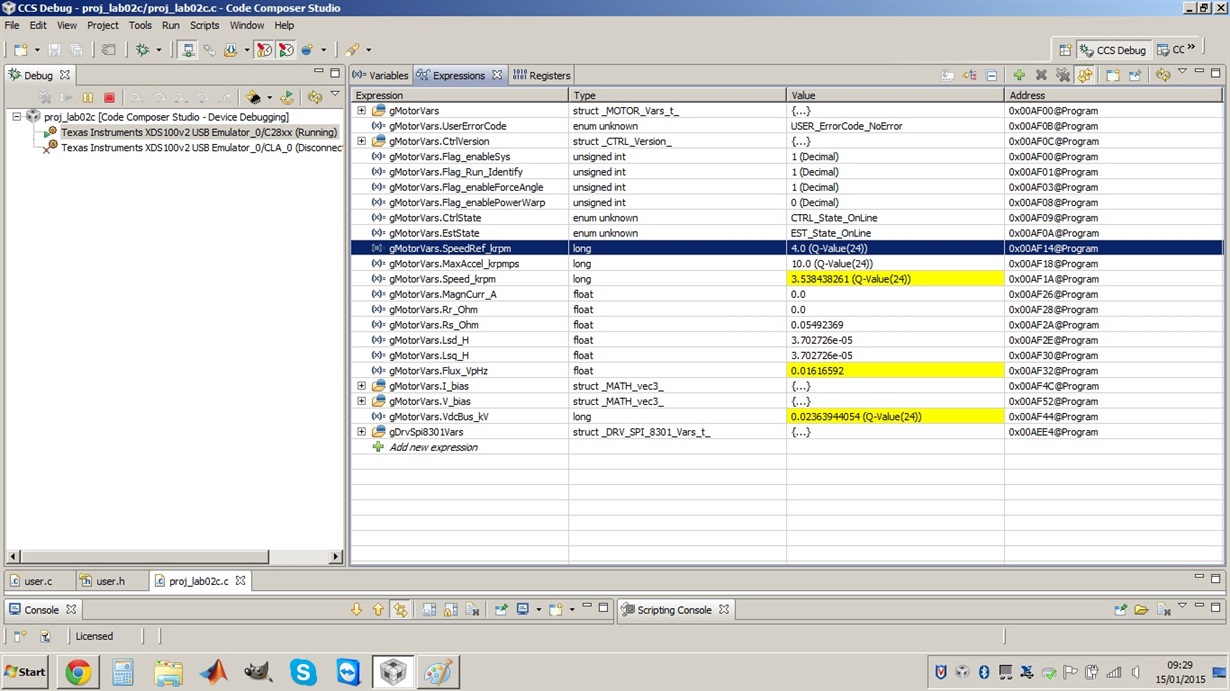

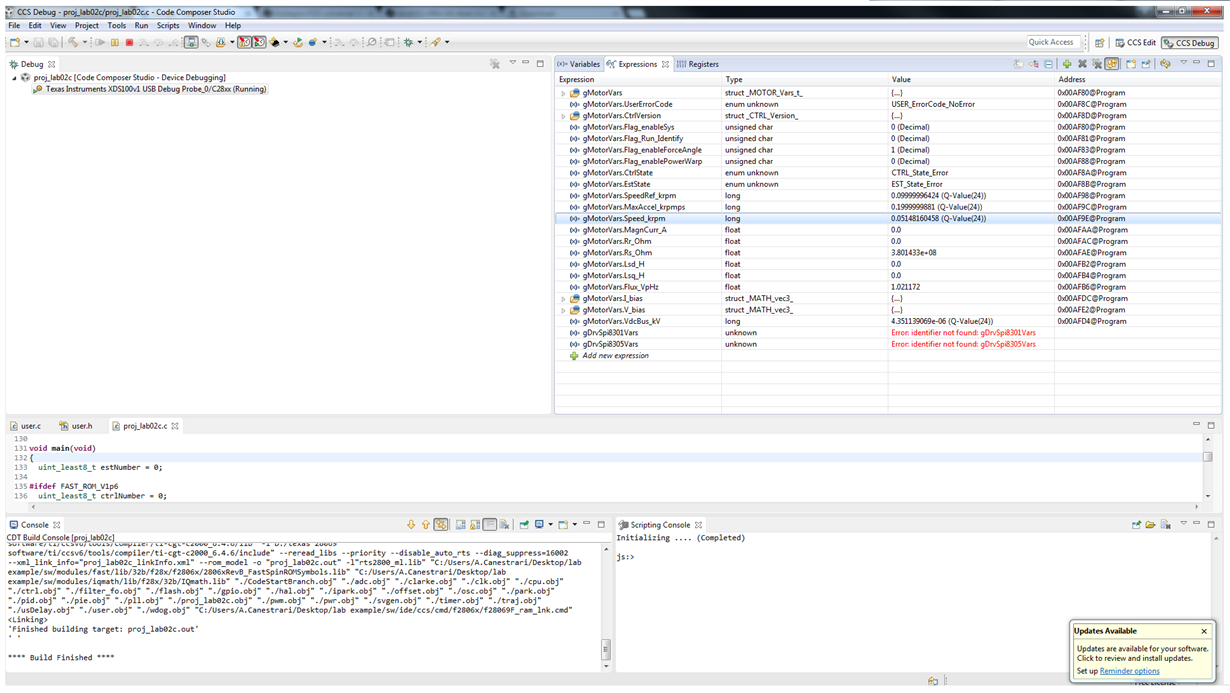

ps. I do not know if this information is relevant or not when they are in the discovery phase of the flow and the inductance from gMotorVars.EstState EST_State_RampUp my power supply goes into protection despite having set as value 3 A> on the setting in the user file I have attached...