Hi,

I’m using HV kit with a Kollmorgen VLM33J Servo Motor. I’m presently running Lab 12b with an encoder although the problem I’m seeing is the same sensorless. At high speeds, under load, the current signal becomes non-sinusoidal and the motor never reaches set point speed.

For example:

No load, 1800 RPM set point, speed is 1800, current is sinusoidal. All is OK!

No load, 1900 RPM set point, speed is 1878, current is not sinusoidal.

1 Nm load, 1800 RPM set point, speed is 1800, current is not sinusoidal.

1 Nm load, 1900 RPM set point, speed is 1820, current is not sinusoidal.

At the bus voltage I’m using (160 VDC) the motor is rated 4 Nm and 2500 RPM. So these tests are well below the motor’s ratings. I have USER_MOTOR_MAX_SPEED_KRPM set for 2.5. I have a second encoder to verify the speed measurements. SpeedQEP_krpm always matches the second encoder.

Below is the OK (somewhat sinusoidal) current signal at 1800 RPM set point, No Load:

Below is the odd shaped current signal at 1900 RPM set point, 1 Nm load. The motor runs at 1820 RPM:

Below 1800 RPM the currents look OK and the speed is spot on. Why would the current go from sinusoidal to almost a saw tooth at higher speeds and as a function of load?

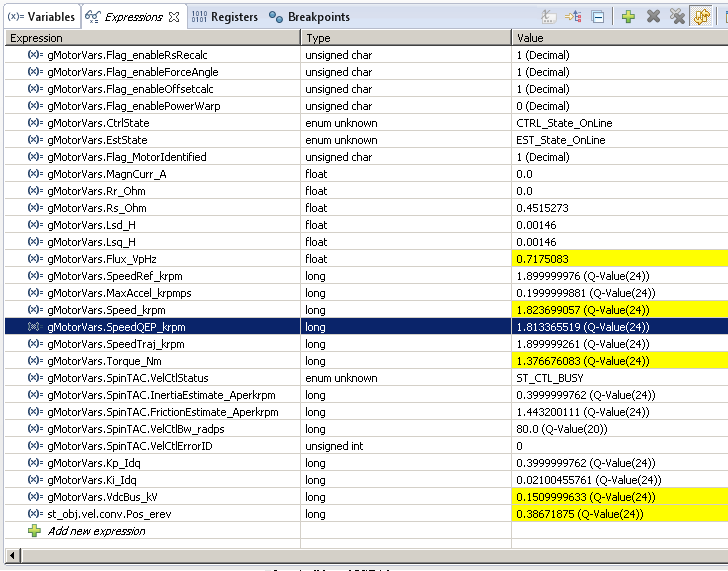

I’ve attached my User.h file plus below a CCS screen shot at the 1900 RPM set point. You can see Speed QEP_krpm is indicating 1.813 in this example.

Thanks for the help.