Other Parts Discussed in Thread: DRV8301

Hello guys

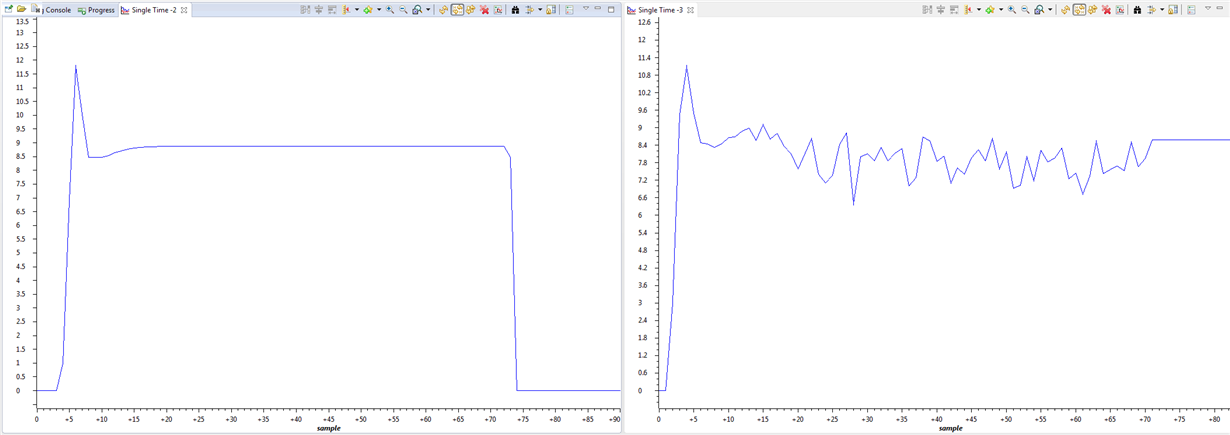

I am using InstaSpin for E-mobility application; this soluction is running on C++ code, keeping the InstaSpin libraries in C code. The user.h file is attached. The solution is working ok, but when the motor speed is close to the motor rated speed the motor phase current looks weird. Using a load (current ripple = 1A), I saved the following pics:

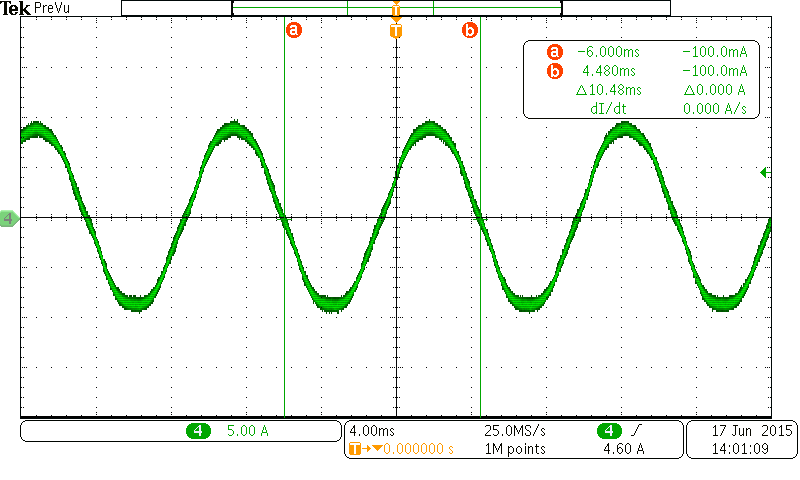

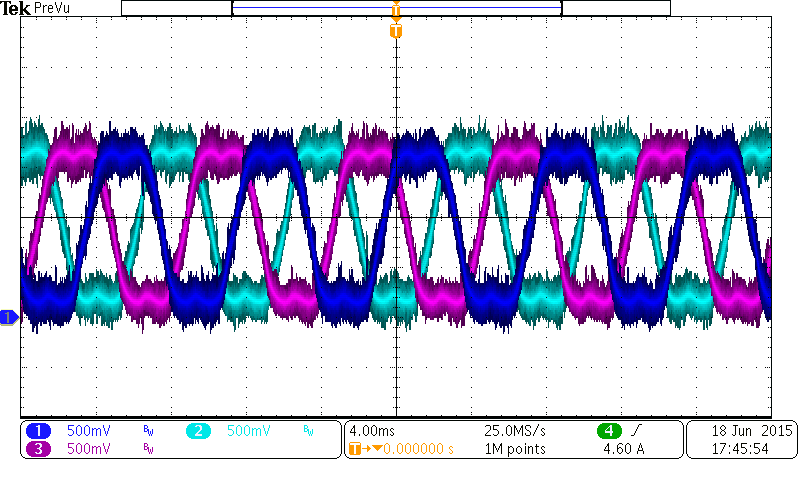

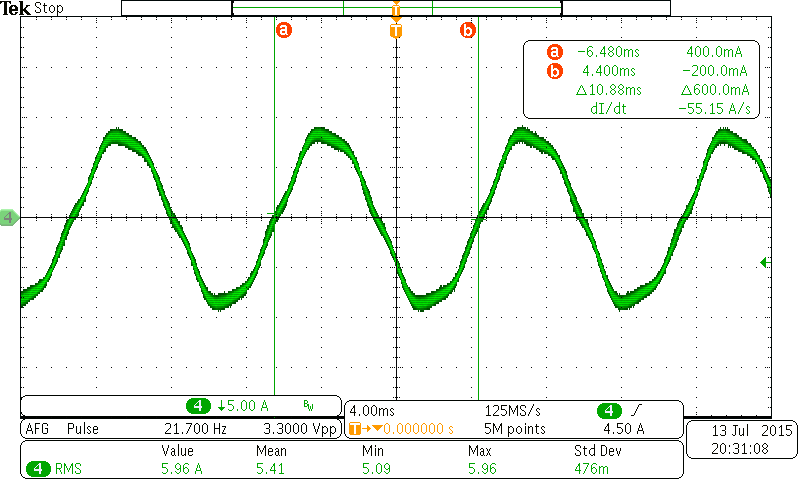

As you can see in figures below, the motor phase current looks ok under Fe= 95.41Hz (10.48ms)

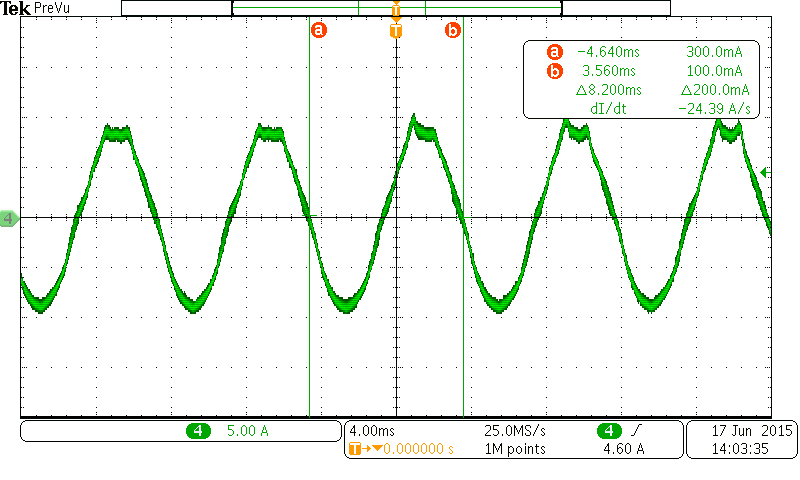

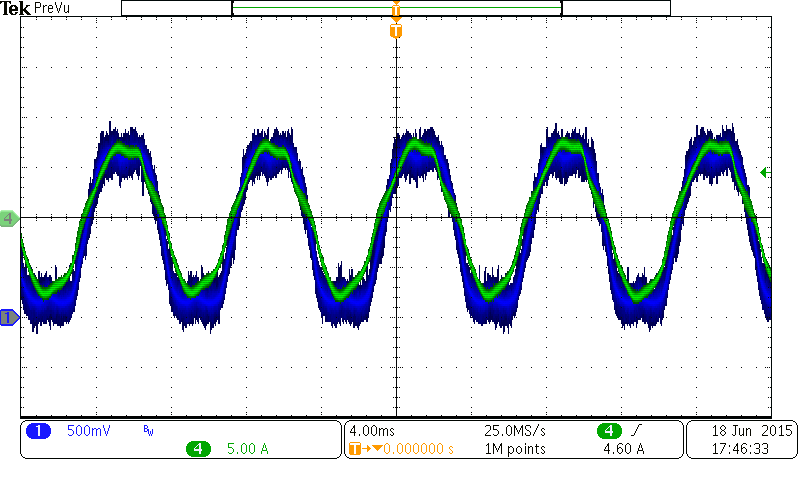

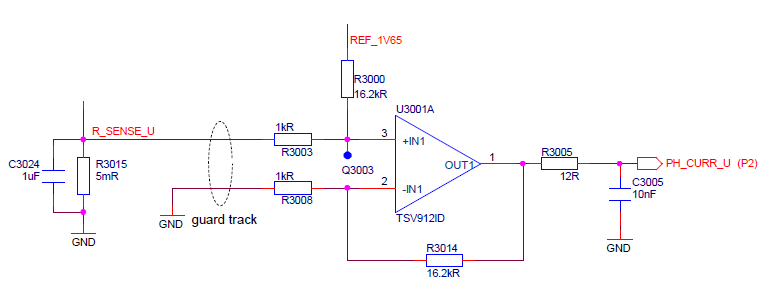

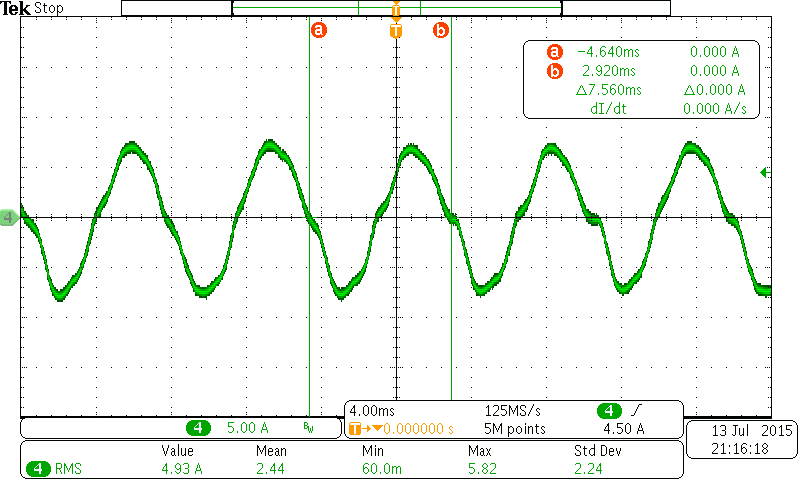

When the motor speed is arround Fe= 121.95Hz (8.2ms), some peaks in the top phase current start to appear (the HW phase current OpAms are in negative scheme):

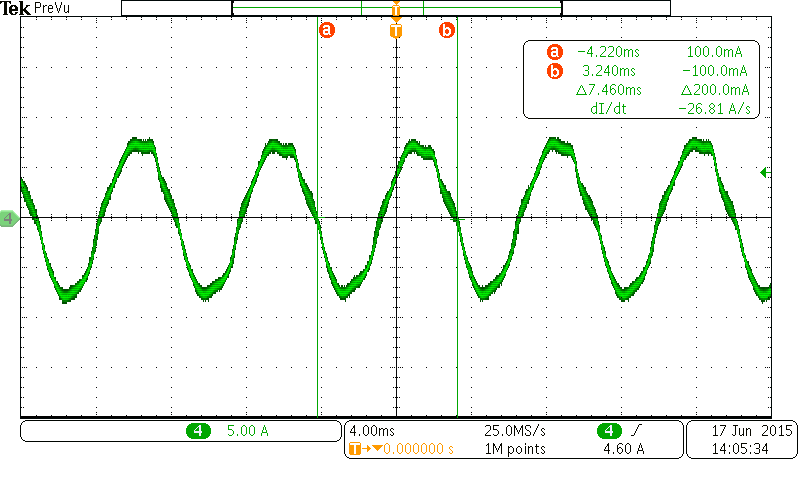

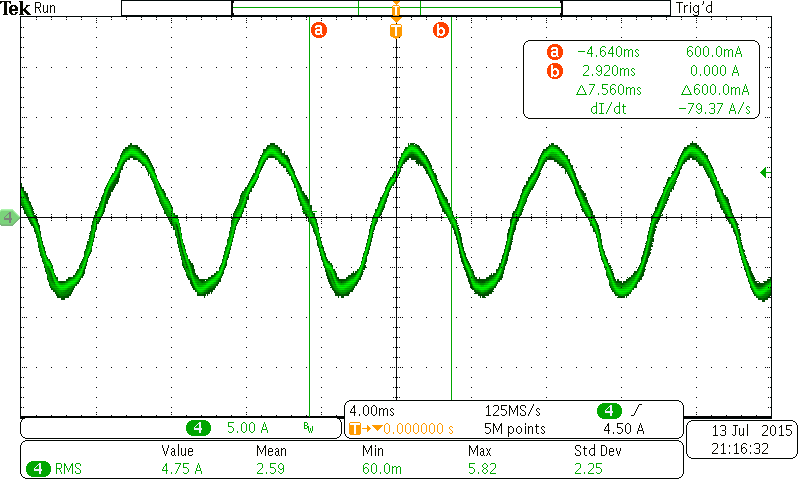

When the motor reach an equilibrium state, the motor phase current looks this:

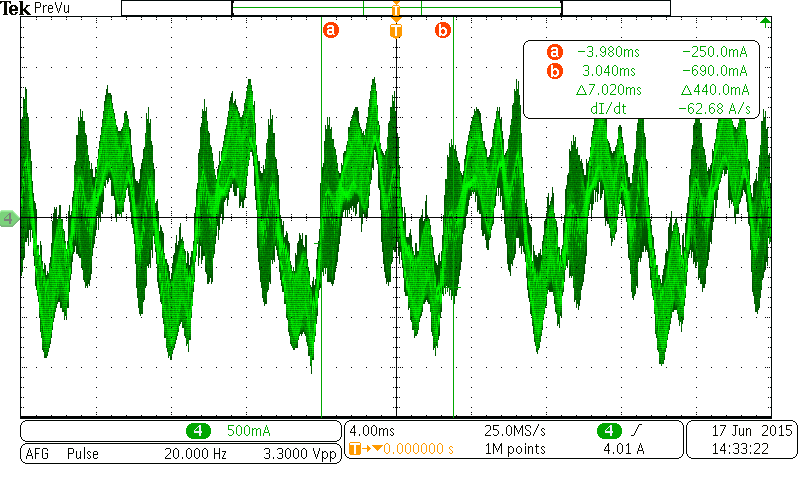

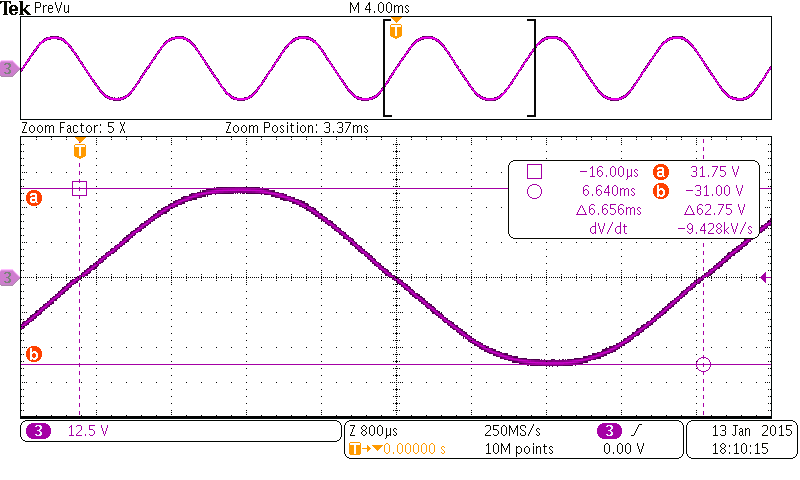

Without any load, the motor reach the maximum speed Fe= 142.45Hz (7.02ms) and phase current looks like this:

I think that back-EMF signal is causing the problem. I already tried to modify the scale factor in the user.h file (SW) and change the voltage sensors calculation (HW) in order to obtain more headroom in the voltage measurement but the result its the same.

1.- What do you recommend to solve the problem?

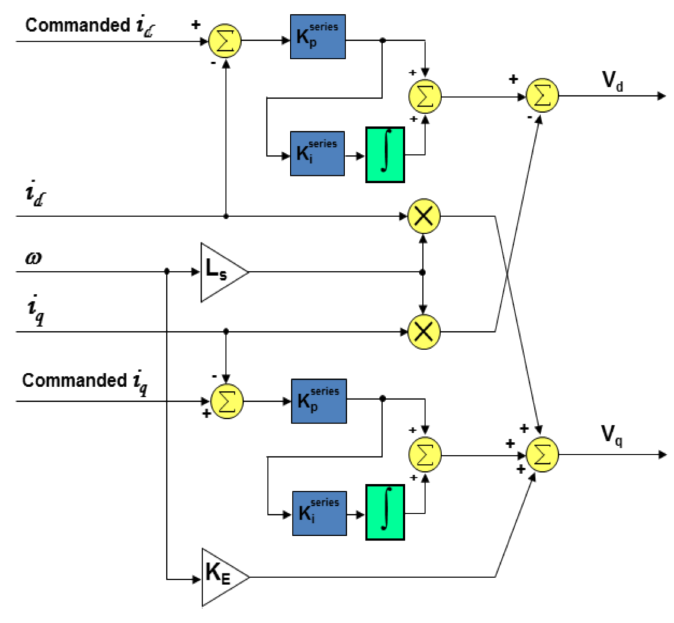

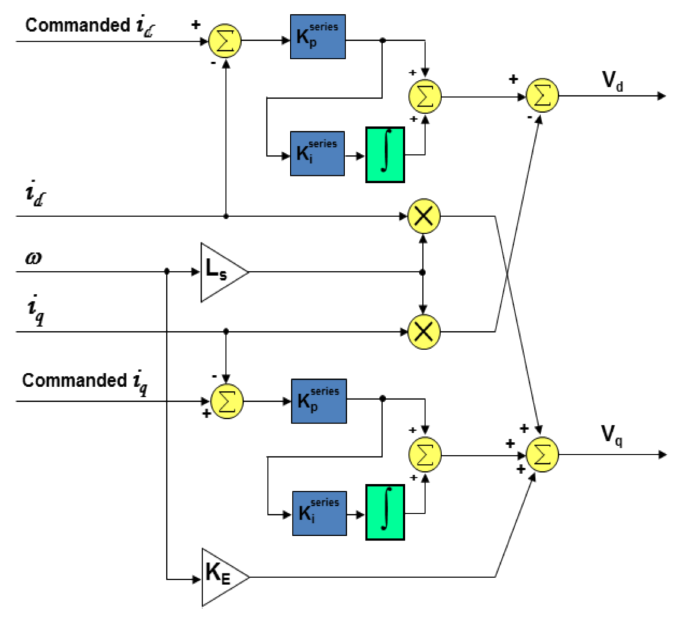

2.- I was reading the InstaSpin documentation (spruhj1f/Figure 11-19) and found this compensation. Is InstaSpin code implementing it?

3.- In case of a negative answer. Do you think that implementing these compensations, could solve the problem?