Hi Sir,

evm : DRV8301-69m-kit

motorware ver : v15

application : e-bike

motor pole pair : 7

user.h USER_MOTOR_MAX_CURRENT (5.0) --> for test

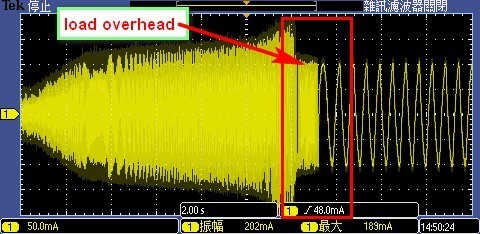

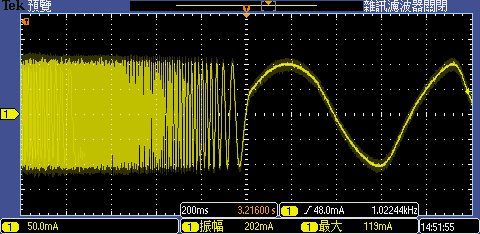

I used lab04. Iq=2.0 the motor run max speed = 3.4Krpm, I increase loader, the speed is no variable. when the loader is overhead , the speed is quickly count down to "0". then release the loader. The speed come back max speed.

I have used lab03b to test as below:

1. Set the SpeedRef_krpm = 3.4Krpm, I increase loader, the speed is no variable. when the loader is overhead , the speed is quickly count down to "0". then release the loader. The speed come back max speed.. That's as the same as the lab04.

2. Set the SpeedRef_krpm = 2Krpm, I increase loader, the speed can count down. When I increase the loader , the speed can be variable.

I don't know why ? If the motor run max speed. I increase the loader the motor can out of control ???

Please help me to solve it, thanks a lot.

summary