Hi,

I'm using a TMS320F28062 on our own PCB.

The Compiler is C2000_6.2.6 under linux.

The software didn't use an OS.

The motor has to drive a pump for medical use.

For testing I drive the motor to a (valid) random speed and stop it for one second and repeat that cycle many times.

For motor startup, forced angle is activated, RS recalibration is enabled, but no RS OnLineRecalibration. The motor parameters are well known.

Mostly the motor startup behaviour is ok. That means, it takes about 100 ms for the RS recalibration before the motor starts.

But sometimes the motor didn't start after RS recalibration is done and the estimator state changes to "online". The motor moves only a little bit and starts turning 2 seconds after the estimator has changed to online state.

Is there a mechanism that the RS online recalibration flag is set to true automatically by the estimator ?

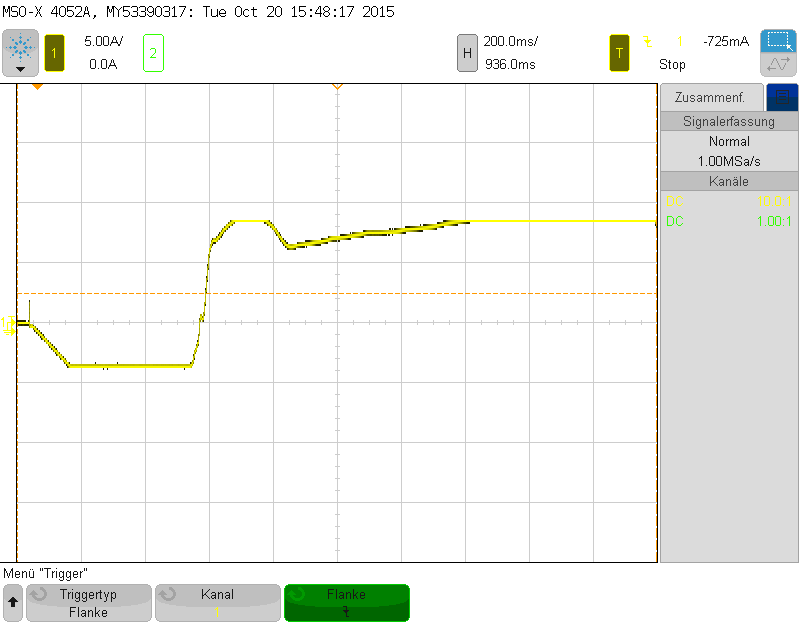

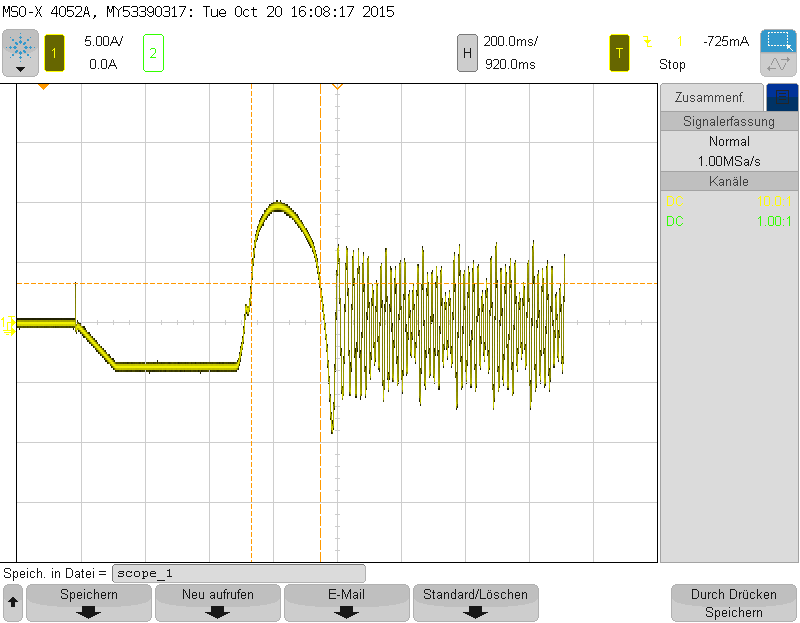

For better explanation see the following graph

Debug1 is the commanded speed (It's equal and drawn below the speed reference in the MotorVars structure)

Debug2 is the speed Reference

Debug3 is the estimator speed

Debug4 is the estimator state (multiplied by 1000)

You see, that normally the Motor starts spinning when the estimator state changes from 3 (RS recalibration) to 13 (online). But in the error case the motor didn't start at this time but there is a little movement. 2 s later the motor starts turning.

What could be wrong ?