Hello,

I am using the LAUNCHXL-F28069M with my own power board to control the velocity of a traction AC Induction Motor ( 6.9 kW - 28V - 190A).

My project is based on lab12b and it is working with certain limit of velocity (about 1500 rpm) with the Magnetizing current of 45A.

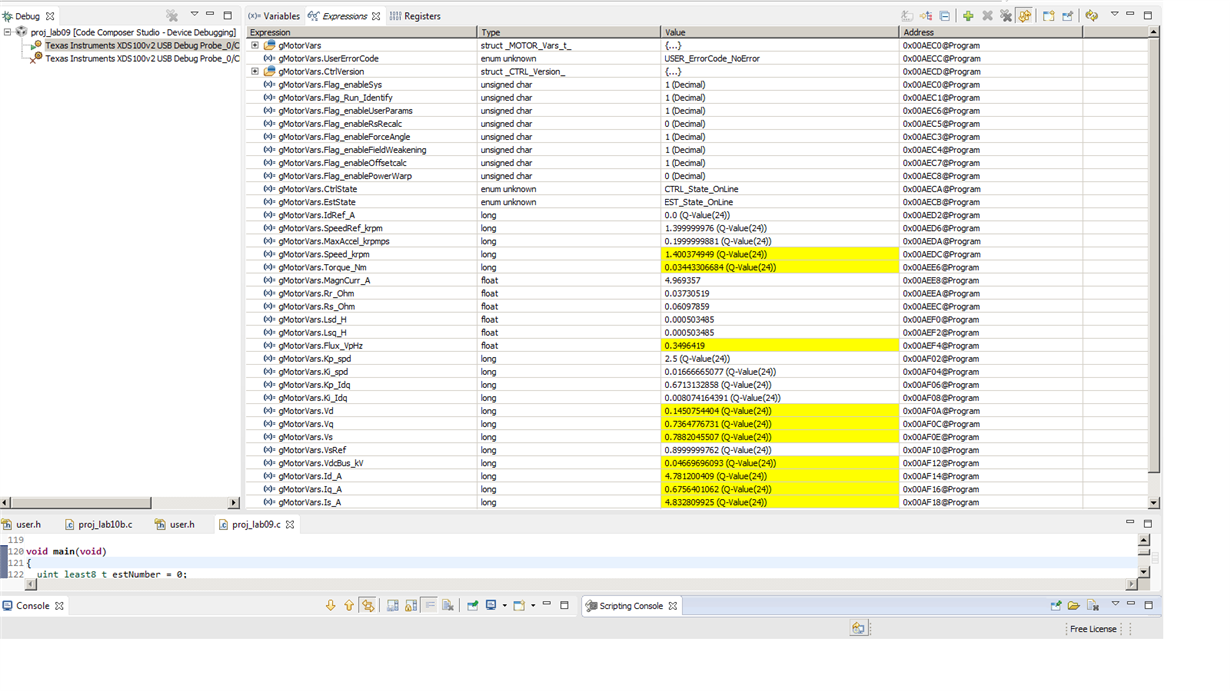

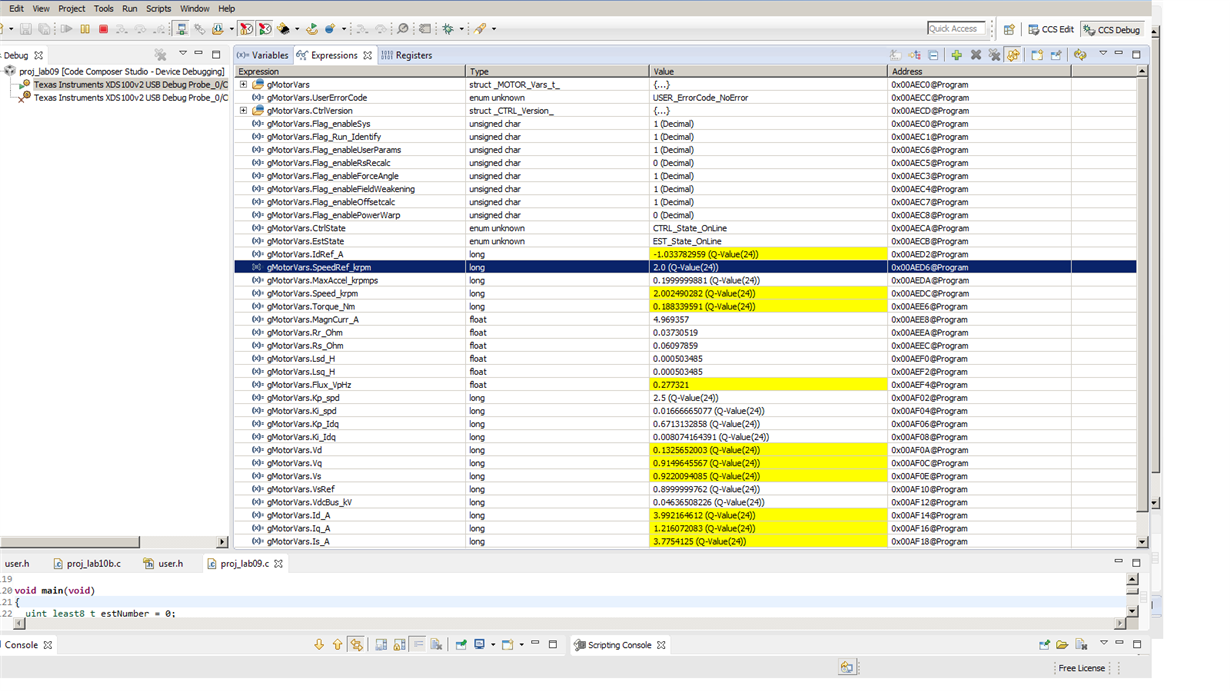

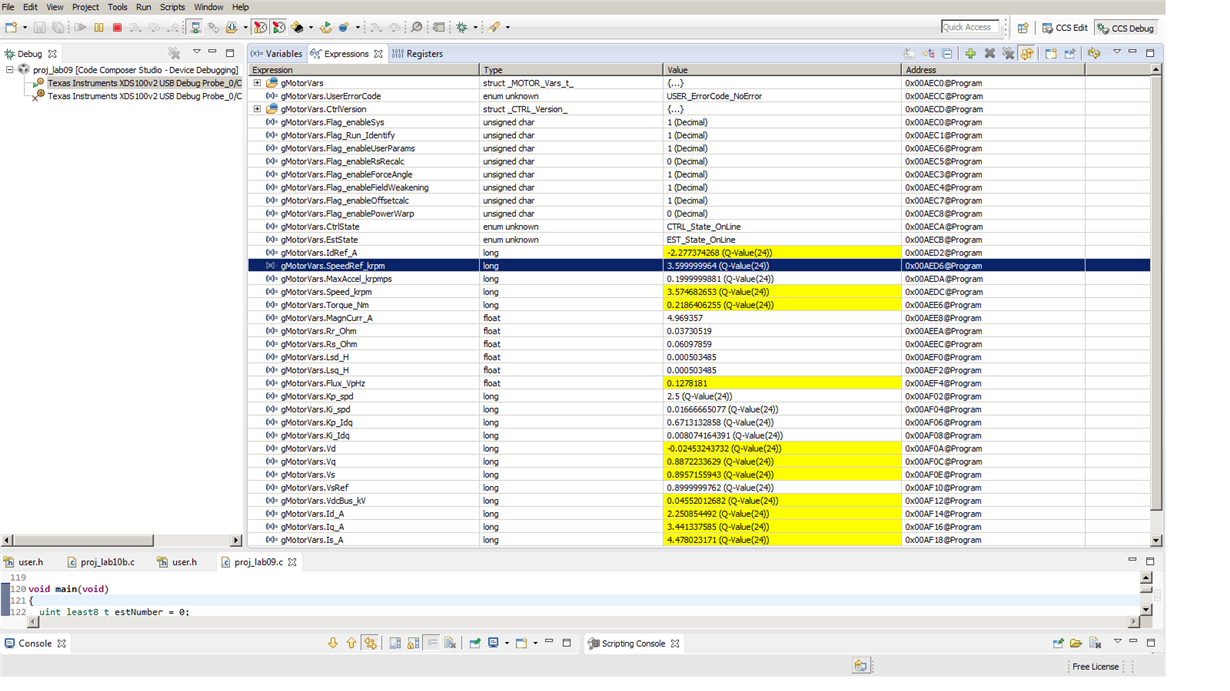

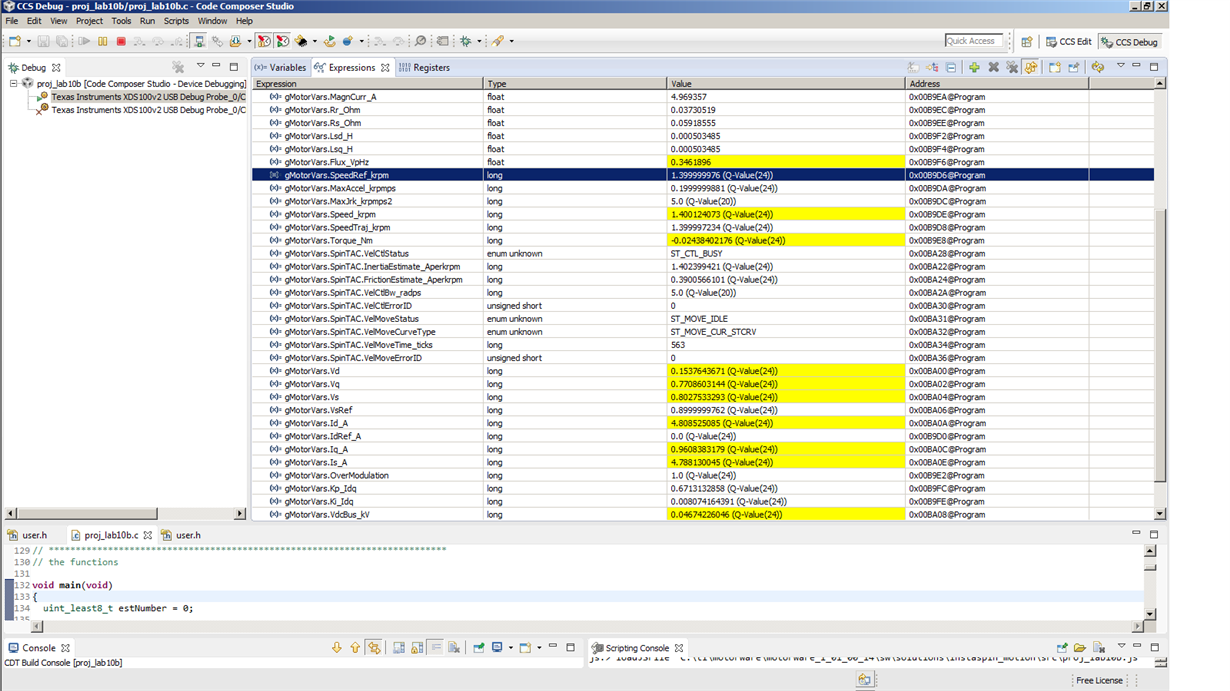

I need to increase the speed about 3600rpm. I've tried with lab9 and it worked fine but with SpinTac ( lab10b) it didn't work.

When I set gMotorVars.Flag_enableFieldWeakening = 1 and the gMotorVars.SpeedRef_krpm over 1500 rpm the motor starts to be bad controlled.

How can I found the cause of this problem ?

Thanks in advance !