FOC control can solve the basic control of three-phase asynchronous AC motor, And how to control the motor to give full play to the performance, we need excellent algorithm control.

TI provides a very good control strategy, so that I deeply studied for a long time from zero. When I understand the whole project, I try to change and debug the code in Lab13e.

I cut some of the invisible code, and use my own code to replace some of the important algorithms, such as slip calculation, these algorithms are from some of the papers I read.

I sort out a simple and effective project in Lab13e, and my motor can run very well.

This is the block diagram of my simplified motor control strategy.

In my project, only the rotor resistance, inductance and leakage inductance are used,for the estimation of slip velocity.

The FAST estimation module and the SpinTAC module have been deleted and replaced.

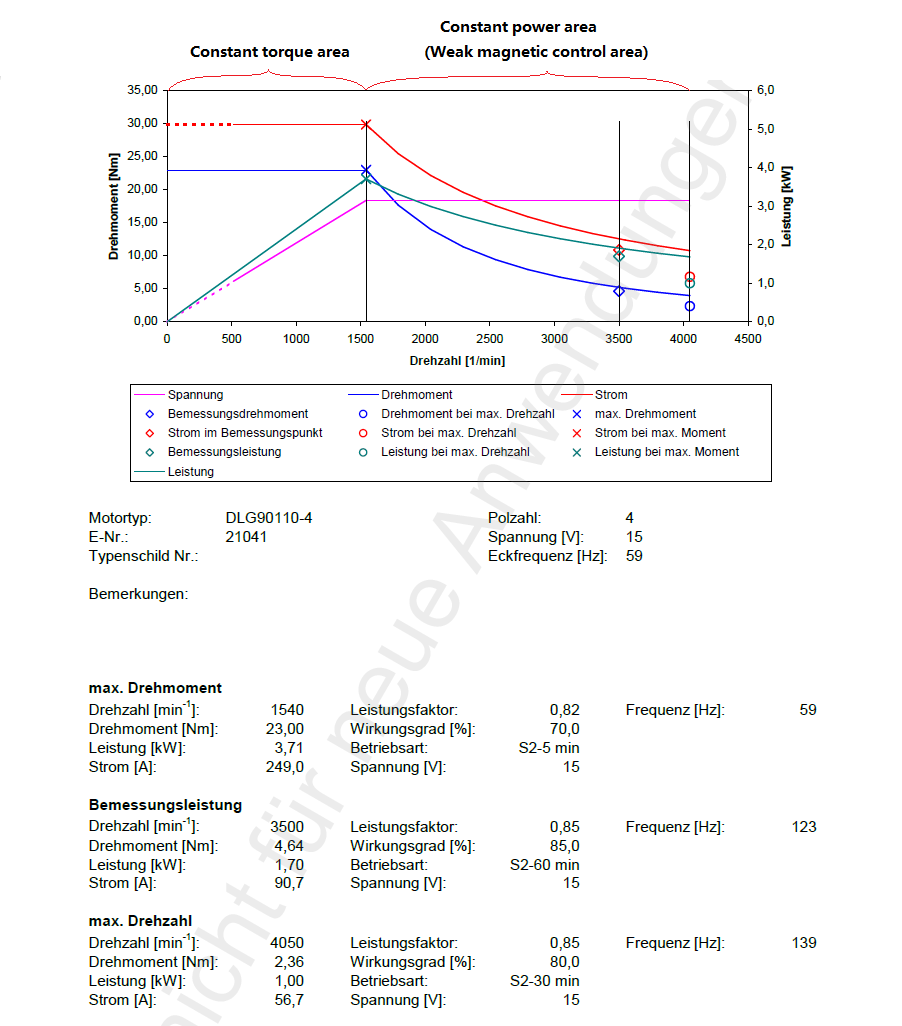

This is the mechanical characteristic curve and the description of the motor used in the experiment.

As shown in the figures, the motor in the constant torque region, the field current(Id) is a constant value, the torque current(Iq) is determined by the speed loop.

If we want to improve the speed of the motor, make the motor work in constant power area,

What we need to do is to reduce the field current(Id) of the motor.

Simple effective Field Weakening control strategy is as follows:

Iq has the following limits:

But I found some phenomena in recent debugging. When the motor is running at 3.5krpm, No matter how I change the value of Id_ref, the motor can not achieve the rated torque(0.67Nm), now the torque is only half of the rated.

Obviously, in 24V, the control is already saturated:

So I improved the bus voltage from 24 to 30V, at this time the motor torque can reach the rated value.

So, If the weak magnetic control is not the reason, what causes the motor torque to be unable to reach the rated value?

I hope that we can discuss this problem, to help me solve this problem.