Kit: DRV8312EVM Rev D

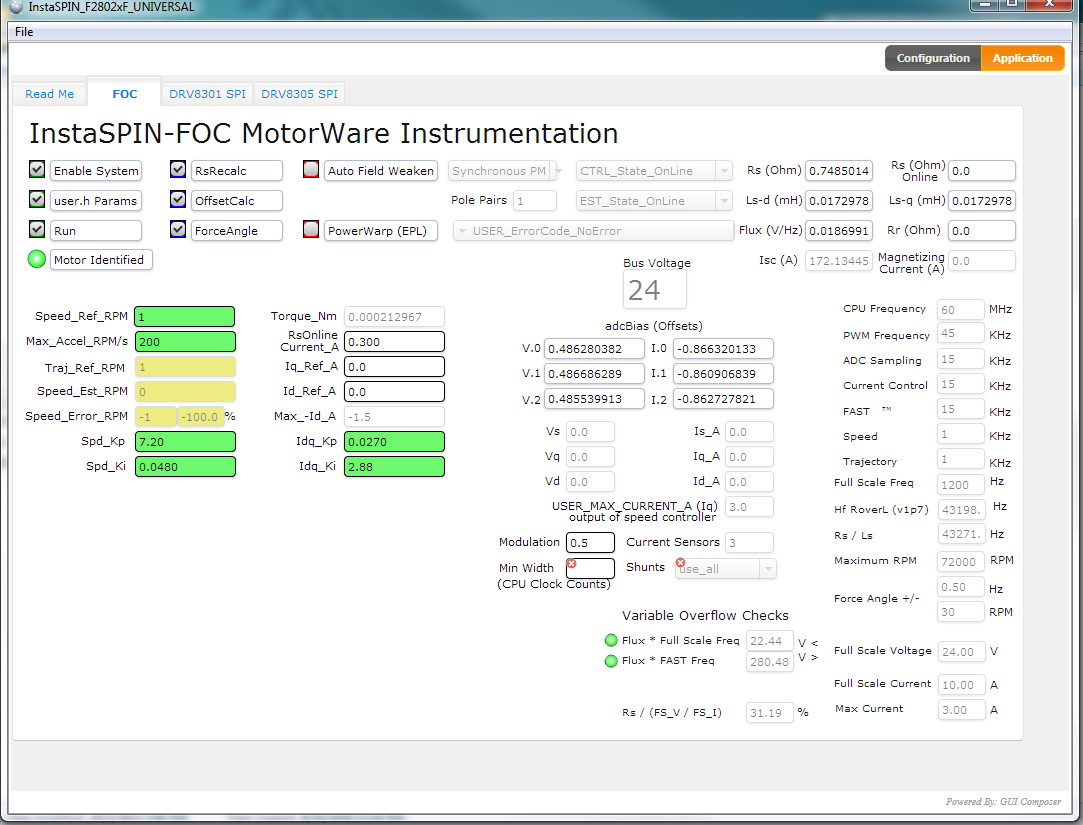

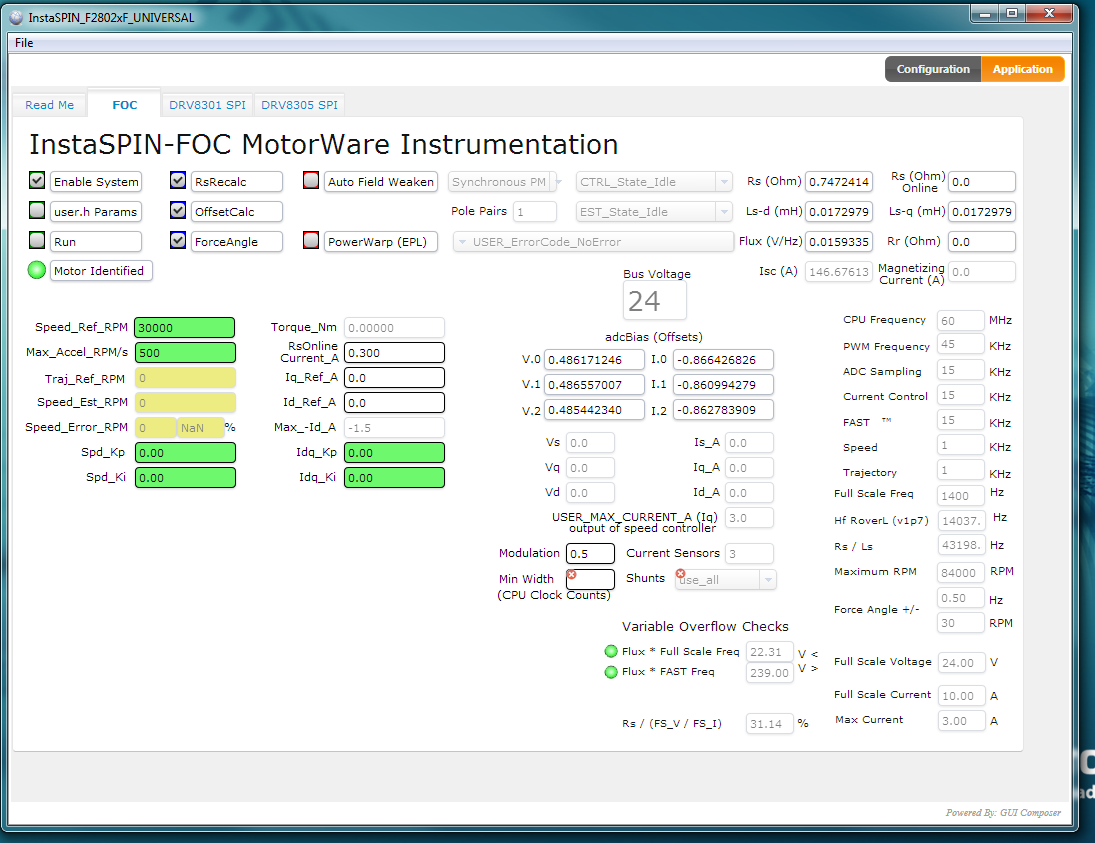

GUI:Instaspin-FOC Motorware Instrumentation

Control card: F2802 (Piccolo A)

I want to run a 24 V 30K rpm bldc motor .I tried ID using program 5b,but during identification the RoverL is always equal to 2000.

And the motor sanity check failed for Rs/Ls.

according to GUI Quick Start guide Instaspin Universal ,I tried to attempt ID using lab 2c but still RoverL came around 12000.

The USER_R_OVER_L_EST_FREQ_Hz is already set at 300.

How should I go further ? Please help

I am g

I am g