Hi

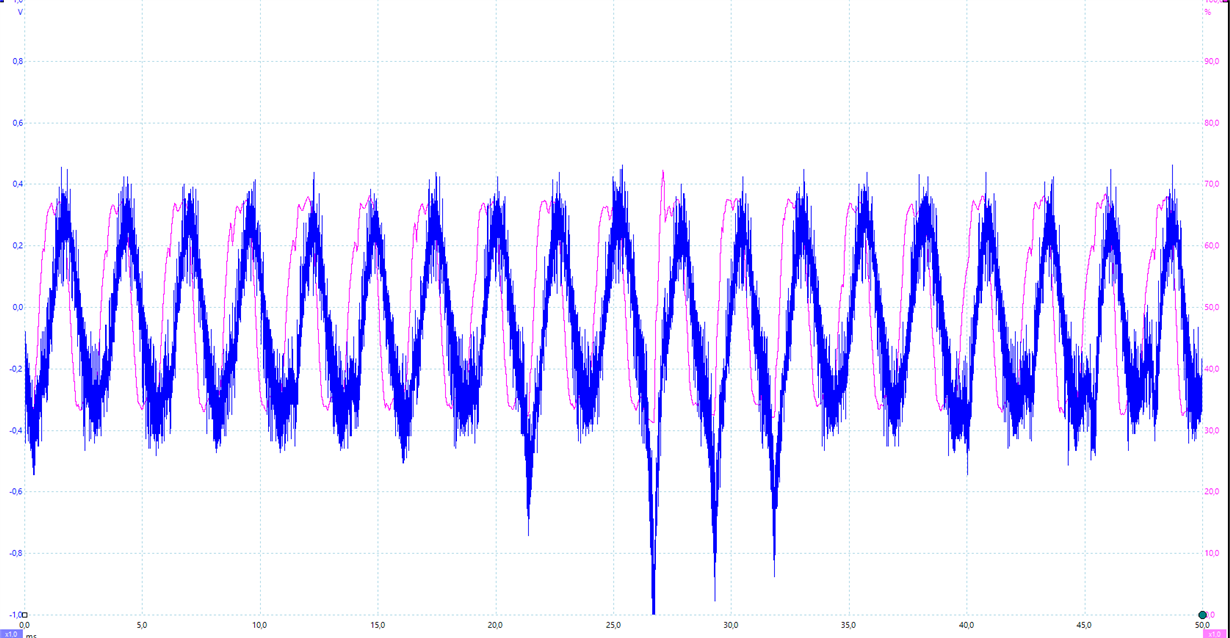

I developed a hardware based on kit DRV8301 RevD using am TMS32028062F (90MHz) prozessor. I have some problems running a motor between 70k RPM and 100k RPM: The current wave form (measured with a current clamp) begins to jump which cause ends in overcurrent after some time. I have two motors from different manufacturer. I have no problem with the weaker one. Maybe because I'm able to operate with a lower Id current.

I'm not sure if the motor parameters are correct because most time lab2b failed to detect Ls_d and Ls_q. Any tips to run a proper ACIM motor identification? Furthermore I'm not sure if the voltage measurement is correct at higher speed because the filter is designed for a lower frequency (USER_VOLTAGE_FILTER_POLE_Hz = 335.648). How do I validate the voltage measurement? Or are the PI-Controller bad optimized?

I set USER_IQ_FULL_SCALE_VOLTAGE_V to bus voltage (48V DC). Is the purpose of this value to limit the voltage if wanted?

About the flux calculation: user.c (USER_MOTOR_RATED_FLUX < (USER_IQ_FULL_SCALE_VOLTAGE_V / (float_t)USER_EST_FREQ_Hz / 0.05)) limits the calculated flux to a value of 0.4 (= 48 / 24kHz / 0.05). My calculation: 0.816 * 48V / 1666Hz = 0.023. Is this calculation correct? I'm running mainISR @ 24kHz so I set ratedFlux to 0.4. Does this setting have any negative side effects?

I recognized that FAST estimates a lower Speed than measured: @ 51k RPM mueasured FAST estimates 50k RPM; @ 103k RPM measured FAST estimates 100k RPM. Is this variation in tolerance or is it a hint that any setting or motor-Id has a wrong value?

Motor:

- Type: ACIM; One Pole Pair

- Max Speed: 100k RPM (1666Hz)

- Rated Flux: 0.023 (I have to use a value of 0.04 caused through the "low" ISR frequency)

- Rated Current: 3.5A

- Max Current: Weak motor 11A; Strong motor: 16A

- Ls_d/Ls_q: Weak motor: ~20uH; Strong motor: ~100uH

- Bus Voltage: 48V DC

Hardware:

- Frequency PWM: 24kHz

- Frequency ISR: 24kHz

- Inverter: DRV8301

- Current measurement optimized for 20A max (8mOhm Shunt)

- Voltage measurement filter copied from DRV8301_RevD kit (USER_VOLTAGE_FILTER_POLE_Hz = 335.648

Software:

- Based on lab11a

- No PowerWarp; No Rs-Online

- Overmodulation: 0.5774 (100% Duty Cycle)

- USER_IQ_FULL_SCALE_VOLTAGE_V = 48V

Regards Andreas